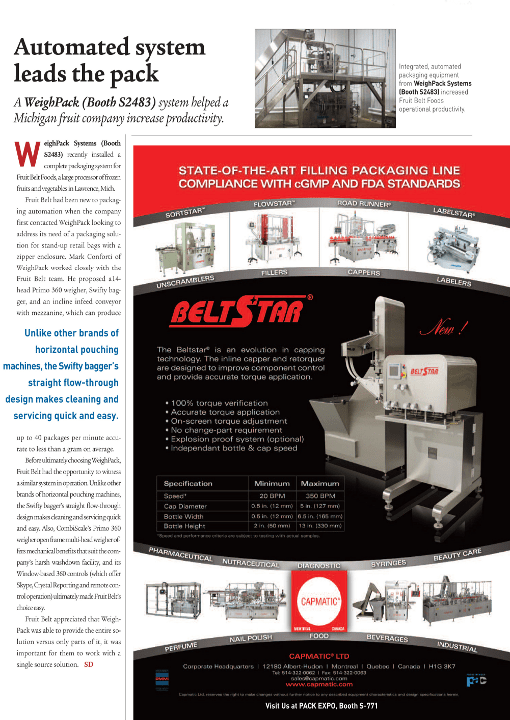

A WeighPack (Booth S2483) system helped a Michigan fruit company increase productivity.

WeighPack Systems (Booth S2483) recently installed a complete packaging system for Fruit Belt Foods, a large processor of frozen fruits and vegetables in Lawrence, Mich.

Fruit Belt had been new to packaging automation when the company first contacted WeighPack looking to address its need of a packaging solution for stand-up retail bags with a zipper enclosure. Mark Conforti of WeighPack worked closely with the Fruit Belt team. He proposed a 14-head Primo 360 weigher, Swifty bagger, and an incline infeed conveyor with mezzanine, which can produce up to 40 packages per minute accurate to less than a gram on average.