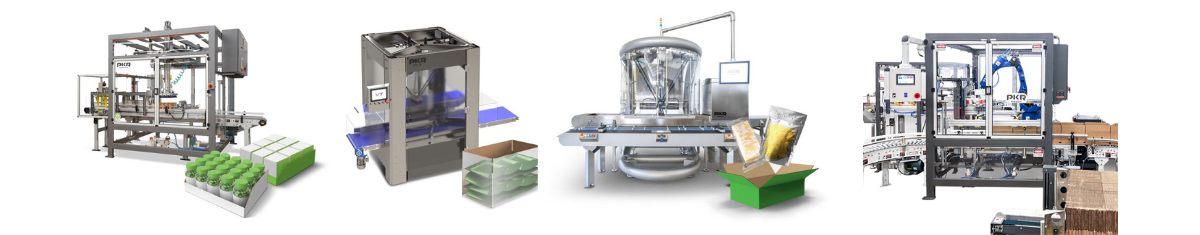

We offer a variety of case packing machines for your production line.

From modular to robotic and automatic to semiautomatic, we can tailor solutions to fit your specific product requirements, available space and budget. We can also design an automated end-of-line system to integrate with our upstream machines or your existing platform.

TOP LOAD ROBOTIC PICK & PLACE CELLS

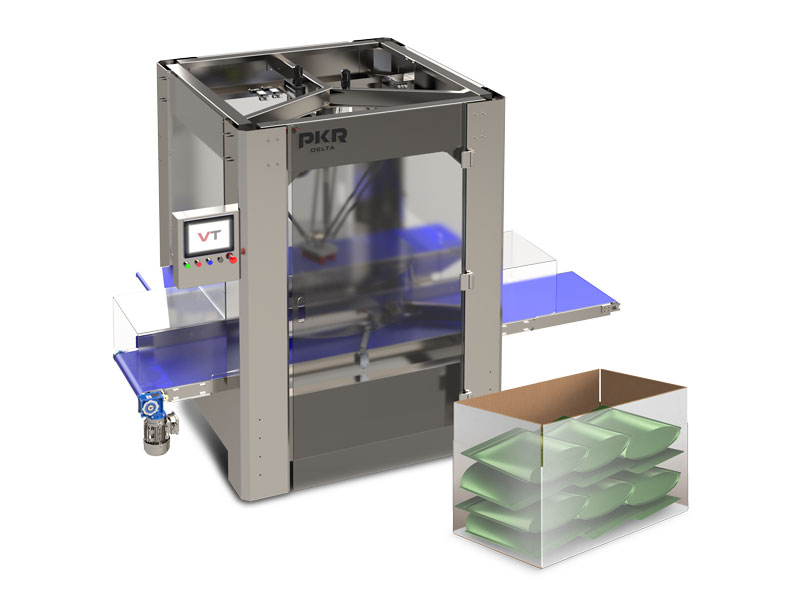

ur PKR modular pick & place cells will automatically top-load your product into cases or trays using our Gantry, Delta, or Articulated Robot.

Our Gantry Robot with X, Y, Z-axis functionality is perfect for your cans, bottles, jars, cartons and similar products while our Delta Robot is the packing solution for your more flexible bags and packages.

Our Delta Robot platform can pack a wide variety of bagged products from snacks to frozen food.

All robotic options provide gentle product handling by either vacuum or mechanical means, assuring product integrity and consistent tray and case packing. And we can configure either option to accommodate a wide variety of case/tray sizes and pack patterns.

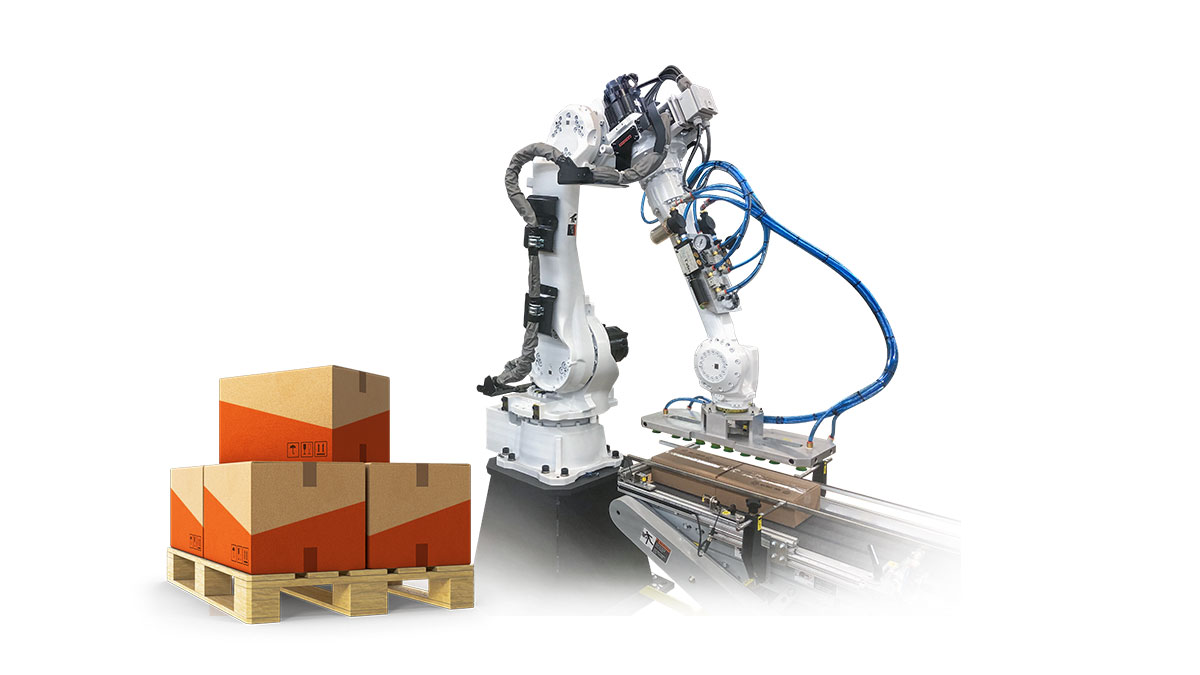

Our PKR Robot pick and place cell with an articulated arm can automatically top-load products into cases or trays in a facility where the height is more limited.

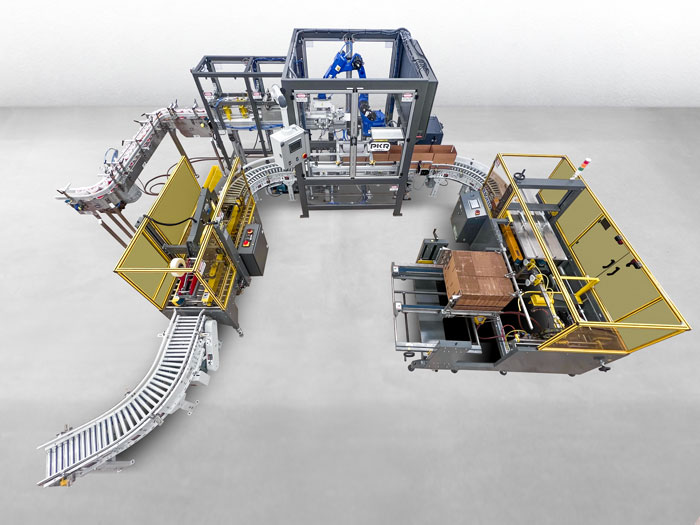

These modular pick & place cells can fit into any existing production line or be integrated as part of a complete packaging solution to include automatic case erecting, tray forming, sealing and robotic palletizing.

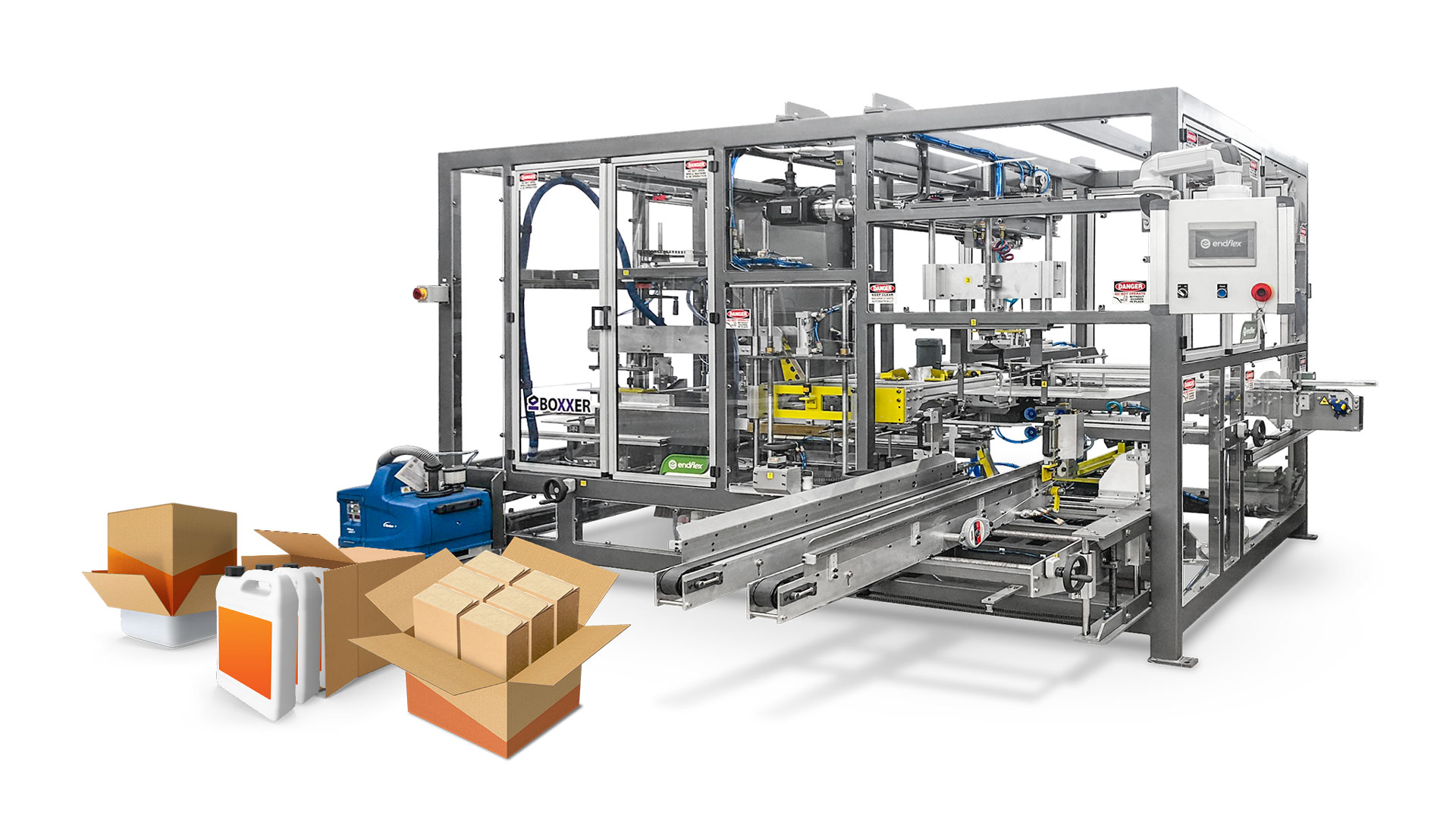

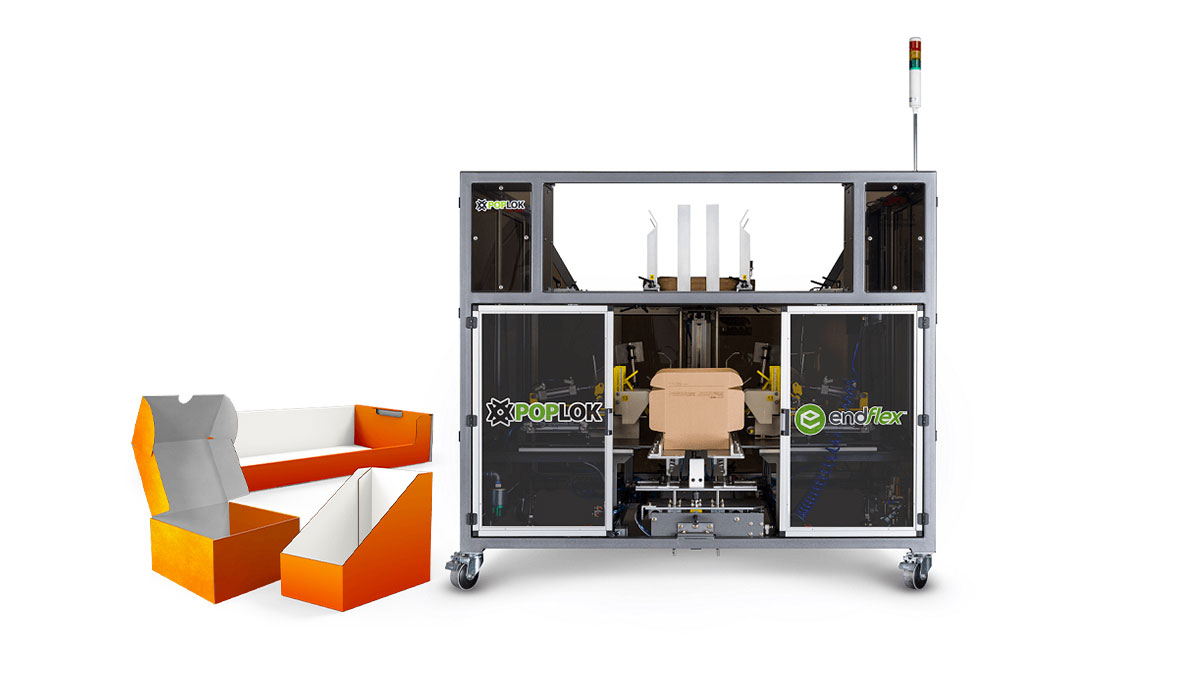

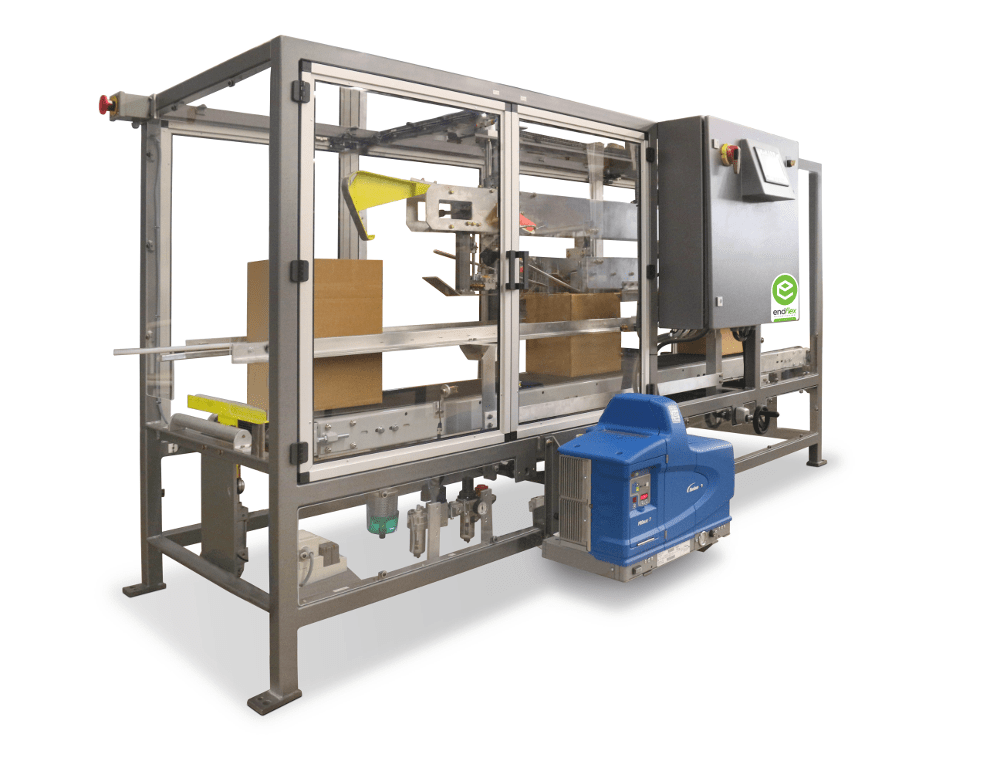

ALL-IN-ONE CASE ERECTOR / LOADER / SEALER

Automatic case erecting, case packing and case sealing in one machine. This compact all-in-one unit can be configured to load your cases from the top, the side or the bottom and takes up minimal space in your facility.

Load your containers, cartons, jugs, bottles and more with this efficient unit.

A perfect fit for our complete end-of-line container filling system to take your filled cartons and pack them into formed cases and seal them prior to palletizing.

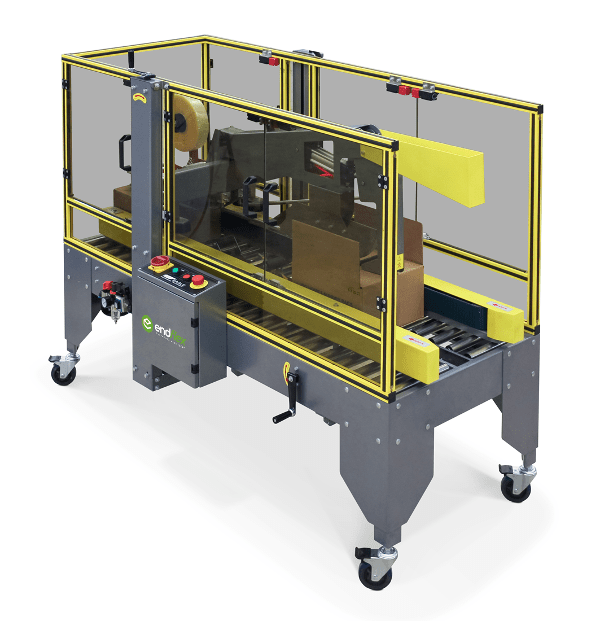

SEMI-AUTOMATIC CASE PACKING SOLUTIONS

The semiautomatic case packers combine case erecting, hand packing and tape sealing into a compact and efficient work cell. This ergonomically designed pick and pack system features an automatic indexing system that positions cases and products for optimal operator comfort, minimizing repetitive wrist and arm motions.

Be more efficient with the flexible BoxxPak case packing system! Stop the chaotic and inefficient case packing process from a rotary turntable and use the BoxxPak to increase production rates, reduce human loading errors, streamline your packaging process and improve operator satisfaction while reducing stress.

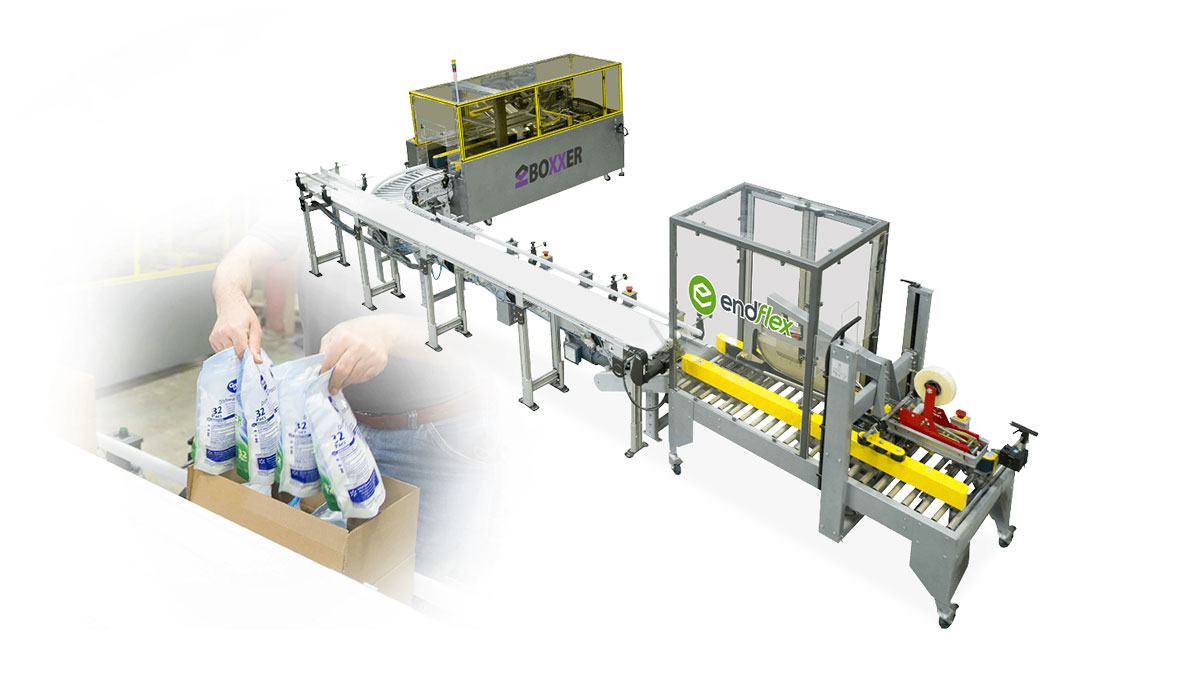

OPTICAL COUNTING & CASE FILLING

Our unique optical counting case packing machines include a horizontal infeed conveyor, optical counter and product staging station to ensure you obtain a perfect count of products for every dispense. Ideal for loose-fill applications of pouches, packets, cartons, hardware and other products that require precise counting and loading.

Easily integrate our feeding system with the Boxxer tape or glue case erector, case indexing conveyor and case sealer for a complete system solution.

GRAVITY DROP PACK CASE PACKER

We offer automatic and robotic case packing machines specifically engineered for today’s end-of-line packaging needs. Our modular drop packing solutions are designed to case pack a wide variety of products packaged in pouches, bags, cartons, boxes, jugs and containers.

These machines can be integrated with any downstream case erecting system and customized to run at your required output. Our drop case packers can also glue or tape your corrugated case at efficient speeds with minimal required maintenance.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.