PopLok

For Big or Small Shippers & Retail Trays

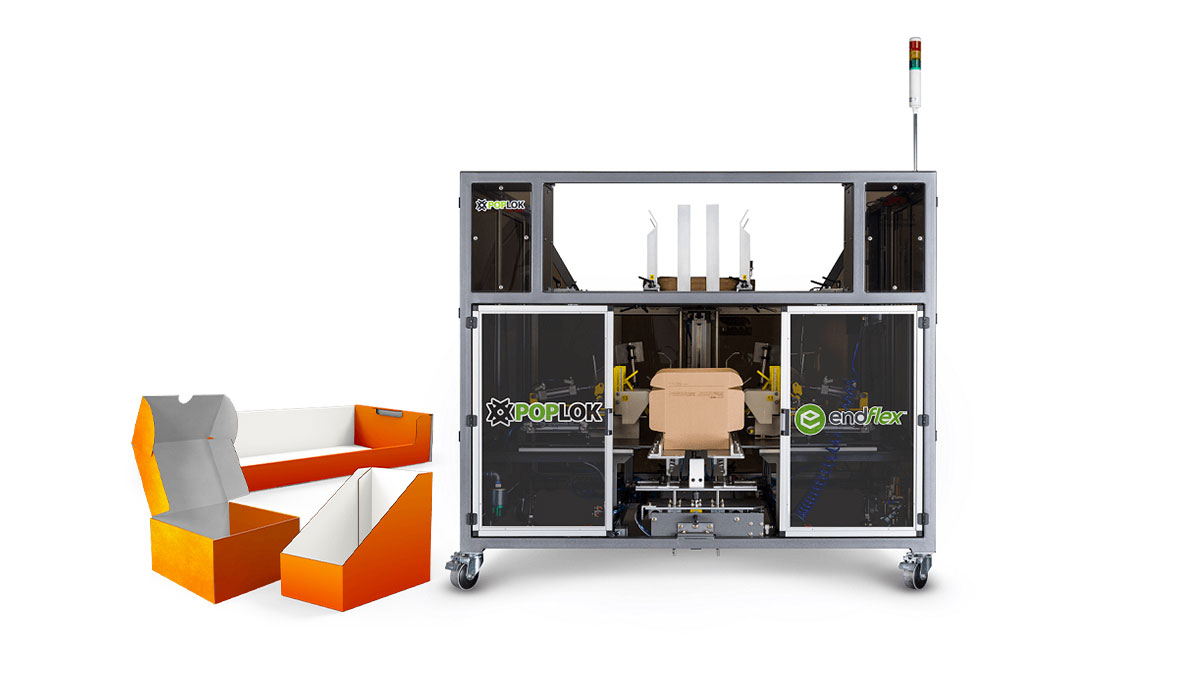

The Poplok family of fold and tuck tray forming machines for display trays and shippers are engineered to automatically form die cut trays at rates up to 1,200 per hour. The PopLok is commonly used for two applications:

Shippers & Mailers: Ideal for e-commerce and home delivery, the PopLok forms die cut blanks into finished lidded trays that are convenient for mailing while greatly reducing manual labor.

Display: The PopLok can produce a wide variety of display trays from simply flat bottom trays for containers to sophisticated 5 tuck trays with back display walls and inserts. Stop making corrugated trays by hand and invest in the PopLok automatic tray former!

Videos

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

-

Ideal Markets

-

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

PopLok

For Big or Small Shippers & Retail Trays

Videos

The Poplok family of fold and tuck tray forming machines for display trays and shippers are engineered to automatically form die cut trays at rates up to 1,200 per hour. The PopLok is commonly used for two applications:

Shippers & Mailers: Ideal for e-commerce and home delivery, the PopLok forms die cut blanks into finished lidded trays that are convenient for mailing while greatly reducing manual labor.

Display: The PopLok can produce a wide variety of display trays from simply flat bottom trays for containers to sophisticated 5 tuck trays with back display walls and inserts. Stop making corrugated trays by hand and invest in the PopLok automatic tray former!

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

-

Ideal Markets

-

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.