We are an industry leader in premade pouch filling machines, offering solutions for retail, wholesale and bulk packaging.

Designed to meet any production rates, package style and budget, our family of bag filling machines includes the Swifty Bagger® series for laminated pouches with zipper closures and the Bingo Bagger® and Zippy Bagger® for wicket pouches.

We provide solutions to automatically open, fill and seal a wide variety of products including snack foods, powders, spices, coffee, confections, pet food, cheeses, fruits, vegetables, bakery ingredients, frozen foods, liquids, hardware and pharmaceuticals to name just a few.

Swifty Bagger 3600 / 1200 for high performance

The Swifty Bagger 3600 and 1200 pouch filling machines for filling stand-up zipper pouches are engineered for medium to high production rates up to 2,400 bags per hour (higher speed servo model available).

Our unique straight-line design ensures the operator can see the entire bag opening, filling and sealing processes without the assistance of others, making it easier to operate, service and clean.

These machines include an easily accessible bag magazine to ensure every bag enters the machine square, an automatic zipper opening device, a bag shaker at the fill station for product leveling and an integrated exit conveyor.

The Swifty Bagger stand-up pouch machine can fill DOY pack, SUP and SURP pouches, pillow, gusseted, quad and carry handle.

For mechanical rates up to 2,700 bags per hour

Swifty Bagger Box Gusset for side gusset bags

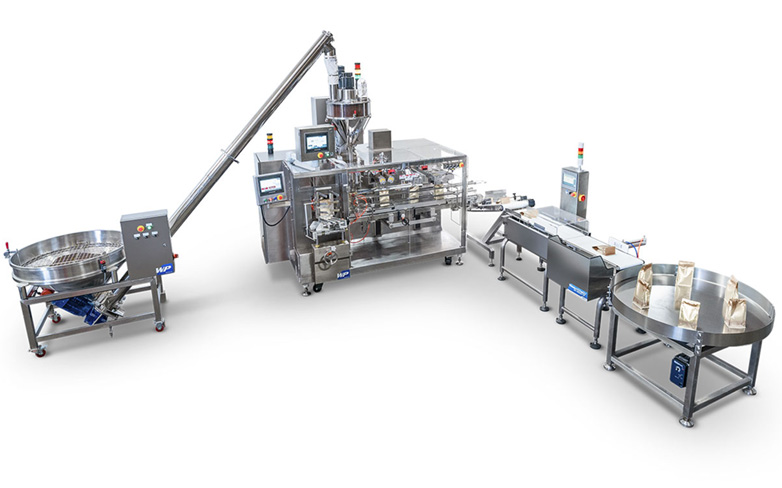

Automatically fill side gusset bags with block bottom, with or without a pocket zipper with our Swifty Bagger Box Gusset.

Designed to automatically open, fill, tuck and seal side gusset bags, this unique machine features an easily accessible bag magazine, automatic zipper opener, integrated bag shaker and exit conveyor.

Perfect for packaging coffee and other powder or granule products when paired with our auger powder filler. Match it with our multi-head weigher or linear net weigher and the Box Gusset will also efficiently bag other products such as candy, nuts, baked and dry goods, jerky or even hardware and textiles.

Ask about designing a fully automated system to include our WeightCheQ check weigher and other downstream solutions such as case packing and palletizing.

For mechanical rates up to 1,500 bags per hour

Compact Swifty Bagger MINI

The Swifty Bagger Mini stand-up pouch filling machine is perfect for compact bag sizes. The Mini automatically opens, fills and seals a variety of premade stand-up pouches. With our smallest footprint, this machine occupies only 10 square feet of floor space and easily rolls to fit within your existing production environment.

The Mini is constructed with stainless steel and is easy to use, easy to service and easy to maintain. It features an easy-to-adjust bag magazine for convenient feeding that ensures premade pouches enter the machine perfectly square, resulting in consistent output and seals.

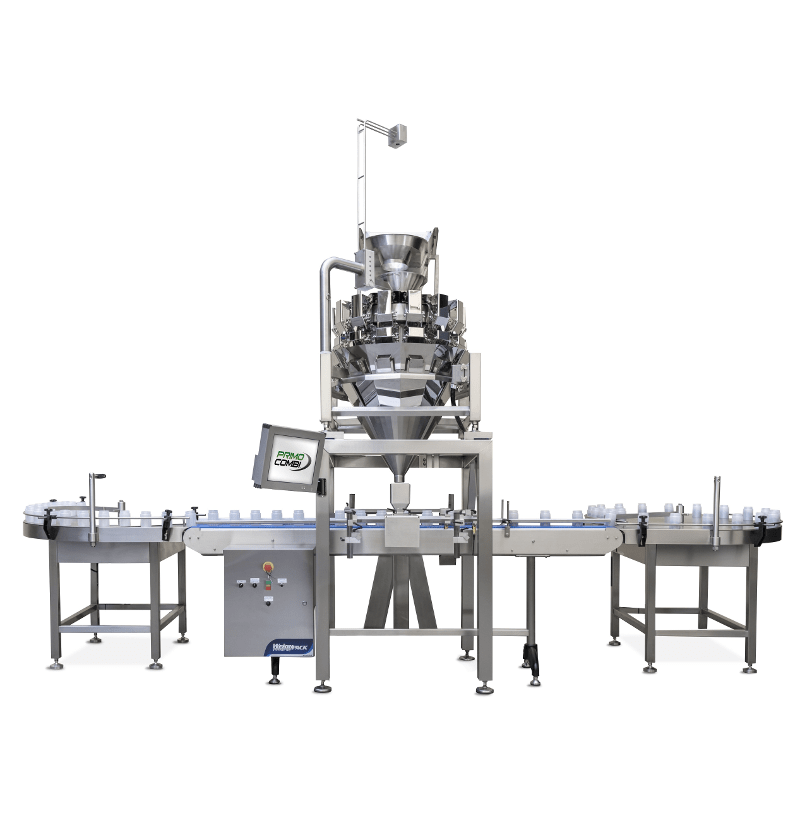

The Swifty Bagger Mini easily integrates with any auxiliary filling machines including our PrimoCombi multi-head weigher, PrimoLinear net weigher and Star Auger for powder filling.

For mechanical rates up to 1,000 bags per hour

Economical Swifty Bagger JUNIOR

The Swifty Junior pouch filling machine automatically opens, fills and seals premade stand-up pouches (SUP, SURP, DOY) in one process, making it easy to use and easy to integrate with multi-head weighing, net weighing and auger filling machines.

The Swifty Junior is extremely compact requiring only ten square feet of floor space.

For mechanical rates up to 900 bags per hour

Bingo Bagger for large wicket bags

Designed for applications that do not require sealing to integrate with an existing sealer or locking device, the Bingo Bagger premade wicket pouch bagging machine automatically pulls a vacuum and/or gas flush at the sealing station. This convenient feature is unique in today’s market and greatly reduces labor while improving food safety by eliminating human interaction in the sealing process.

Manufactured with a robust stainless steel frame and food-grade contact parts, the Bingo can fill both polyethylene and laminate materials.

The Bingo Bagger is perfect for foodservice packaging, bulk bagging and is commonly used for cheese, fresh fruits and vegetables as well as meat and poultry.

Zippy Bagger for retail wicket bags

The low-profile, compact Zippy Bagger wicket bag filling machine is designed to fill premade wicket pouches with or without zippers.

The Zippy automatically opens, fills and seals both laminated and polyethylene materials and is commonly used for filling products such as frozen foods, hardware, injection-molded pieces, baked goods and snack foods.

For mechanical rates up to 2,000 bags per hour

VS Bagger for higher speed applications

The VS Bagger is the perfect partner to an existing sealing machine or for applications that do not require sealing at all. The VS automatically positions and fills a premade wicket pouch under the fill zone then transfers it to the next station of the packaging process. Reliable and compact, this versatile bagging machine can be easily interfaced with a twist tie, tin tie, Kwik-Lok or horizontal sealer.

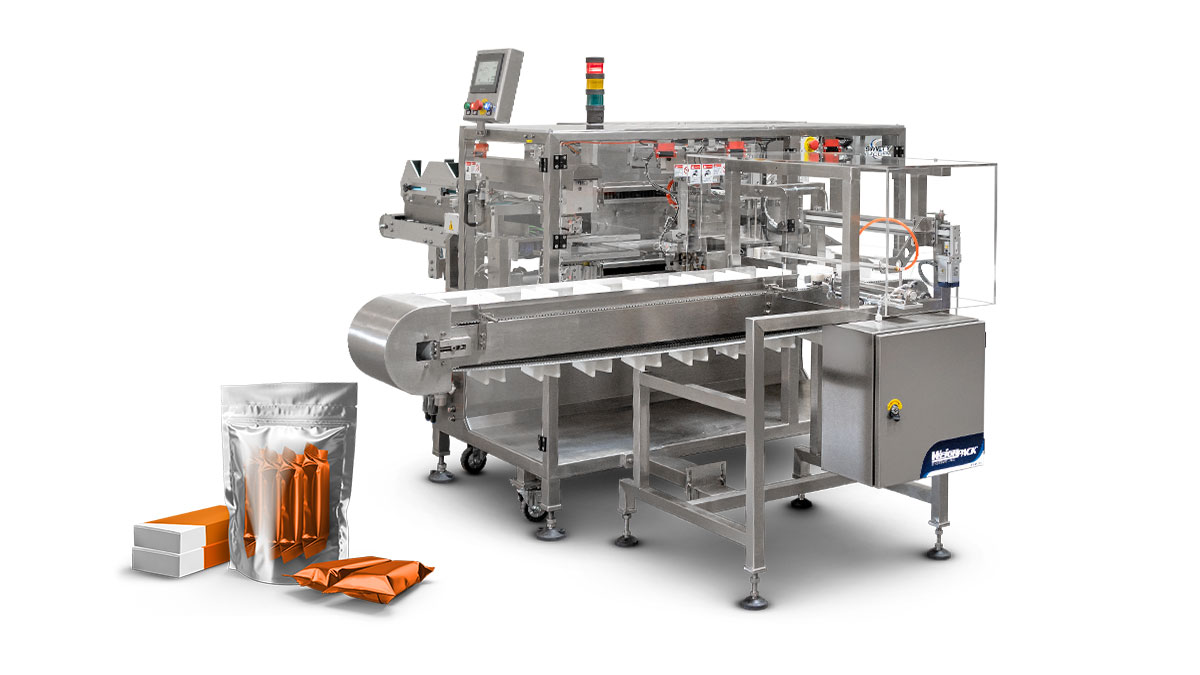

Swifty Bagger Side Load for horizontal loading

Our unique Swifty Bagger Side Load automatic bagging machine is engineered to load and fill pre-made pouches horizontally.

Loading product horizontally creates a distinct appearance within the pouch that works well for marketing pre-packaged snack foods and supplements as well as pet chews and is perfect for products that need to be oriented in a specific direction such as medical devices or printed materials.

Constructed with stainless steel, this machine features a quick bag loading station with vacuum mechanism, a color touch screen and a no bag-no fill sensor. The straight-flow design allows the operator to see the entire filling process from the front side of the machine.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.