Swifty Bagger Box Gusset

for side gusset bags

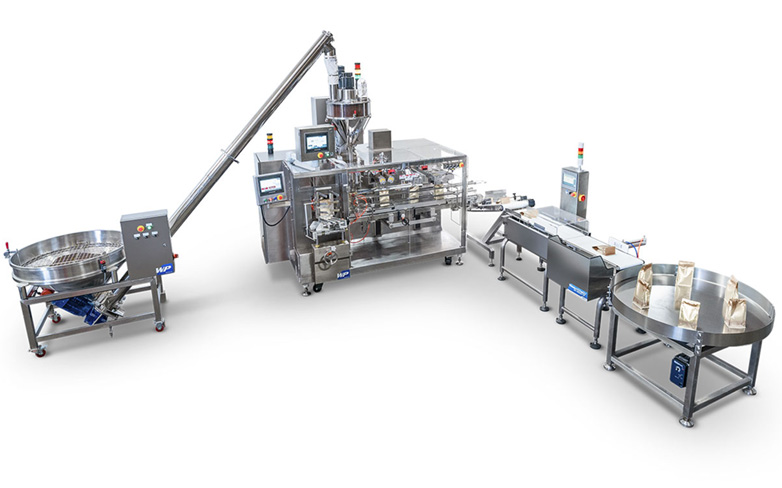

Automatically fill side gusset bags with block bottom, with or without a pocket zipper with our Swifty Bagger Box Gusset.

Designed to automatically open, fill, tuck and seal side gusset bags, this unique machine features an easily accessible bag magazine, automatic zipper opener, integrated bag shaker and exit conveyor.

Perfect for packaging coffee and other powder or granule products when paired with our auger powder filler. Match it with our multi-head weigher or linear net weigher and the Box Gusset will also efficiently bag other products such as candy, nuts, baked and dry goods, jerky or even hardware and textiles.

Ask about designing a fully automated system to include our WeightCheQ check weigher and other downstream solutions such as case packing and palletizing.

For mechanical rates up to 1,500 bags per hour

Videos

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Swifty Bagger Box Gusset

for side gusset bags

Videos

Automatically fill side gusset bags with block bottom, with or without a pocket zipper with our Swifty Bagger Box Gusset.

Designed to automatically open, fill, tuck and seal side gusset bags, this unique machine features an easily accessible bag magazine, automatic zipper opener, integrated bag shaker and exit conveyor.

Perfect for packaging coffee and other powder or granule products when paired with our auger powder filler. Match it with our multi-head weigher or linear net weigher and the Box Gusset will also efficiently bag other products such as candy, nuts, baked and dry goods, jerky or even hardware and textiles.

Ask about designing a fully automated system to include our WeightCheQ check weigher and other downstream solutions such as case packing and palletizing.

For mechanical rates up to 1,500 bags per hour

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- Omron PLC

- Omron safety relay

- Schneider breaker

- Pneumatics component SMC

- Bucker vacuum pump from Germany

- SEW motor drive

- 304 stainless steel frame

- Color touchscreen

- Bag loading magazine

- Bag shaking mechanism

- Gusset bag opener

- Side gusset tucker

- Integrated exit conveyor

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger Box Gusset is suited for all industries as your go to side gusset pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.