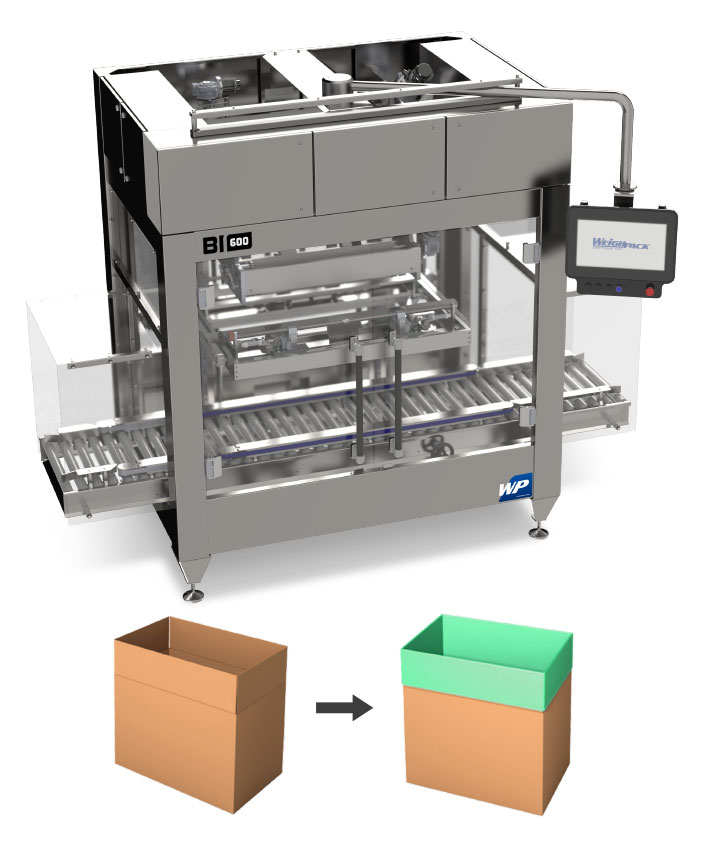

BI 600

Automated Bag Inserter

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

The BI 600 bag inserter dispenses film on a roll, cuts, seals and then inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler, the case passes to the BU 600 bag uncuffer.

Videos

| Parts | Description |

|---|---|

| Box/Tray Length | 300 – 610mm |

| Box/Tray Width | 200 – 410mm |

| Box/Tray Height | 250 – 650mm |

| Film Roll Max Width | 650mm |

| Film Roll Max Diameter | 510mm |

| Film Roll Thickness | 1 – 4mil |

| Tubing Roll Film Width | box/tray length + 16 mm |

| Tubing Roll Film Gusset | box/tray width + 45 mm |

| Tubing Roll Film Fold-Over | 140 – 180 mm |

Features

- Variable speed infeed / discharge conveyor

- Single station fill spout

- Servo drive

- No container—no fill sensor

- Totally enclosed, Lexan safety covers• Safety switches & E-stop

- 304 Stainless steel contact parts

- 304 Stainless steel frame

- Food grade materials

- Full adjustable side rails

- Readily interfaces with weighing equipment

- Anti-vibration leveling pads

- Omron PLC

- Color HMI

*Rates subject to package style, type and size

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Parts Description Box/Tray Length 300 – 610mm Box/Tray Width 200 – 410mm Box/Tray Height 250 – 650mm Film Roll Max Width 650mm Film Roll Max Diameter 510mm Film Roll Thickness 1 – 4mil Tubing Roll Film Width box/tray length + 16 mm Tubing Roll Film Gusset box/tray width + 45 mm Tubing Roll Film Fold-Over 140 – 180 mm Features

- Variable speed infeed / discharge conveyor

- Single station fill spout

- Servo drive

- No container—no fill sensor

- Totally enclosed, Lexan safety covers• Safety switches & E-stop

- 304 Stainless steel contact parts

- 304 Stainless steel frame

- Food grade materials

- Full adjustable side rails

- Readily interfaces with weighing equipment

- Anti-vibration leveling pads

- Omron PLC

- Color HMI

*Rates subject to package style, type and size

-

Ideal Markets

-

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BI 600

Automated Bag Inserter

We have the solution for bagging your bulk quantities of pet food, frozen food, snacks, wrapped candy and much more with this workhorse system.

The BI 600 bag inserter dispenses film on a roll, cuts, seals and then inserts the bag into the case. Once the product is weighed and filled, using a V25 bulk weigh filler, the case passes to the BU 600 bag uncuffer.

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor

*Rates subject to package style, type and size

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

• 304 stainless steel frame

• SMC pneumatics

• Omron servo with absolute encoders

• Hiwin linear bearings

• Impulse sealing for leakproof polyethylene or laminated bags

(1 sealing line, 2-sided active sealing wire)

• V-shaped guillotine knife

• Caseflapholders

• Adjustment indicators

• Light stack – Audible with multicolor*Rates subject to package style, type and size

-

Ideal Markets

-

Our BI 600 machine is suited for all industries as your go to automated bag inserting machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.