Swifty Bagger 3600 & 1200

for high performance

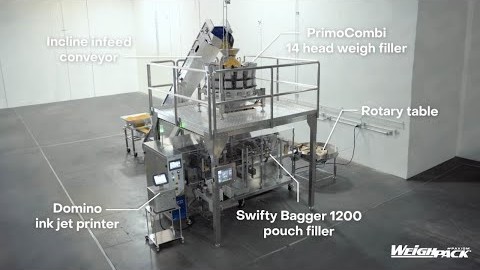

The Swifty Bagger 3600 and 1200 pouch filling machines for filling stand-up zipper pouches are engineered for medium to high production rates up to 2,400 bags per hour (higher speed servo model available).

Our unique straight-line design ensures the operator can see the entire bag opening, filling and sealing processes without the assistance of others, making it easier to operate, service and clean.

These machines include an easily accessible bag magazine to ensure every bag enters the machine square, an automatic zipper opening device, a bag shaker at the fill station for product leveling and an integrated exit conveyor.

The Swifty Bagger stand-up pouch machine can fill DOY pack, SUP and SURP pouches, pillow, gusseted, quad and carry handle.

For mechanical rates up to 2,700 bags per hour

Videos

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

Swifty Bagger 3600 & 1200

For High Performance

Videos

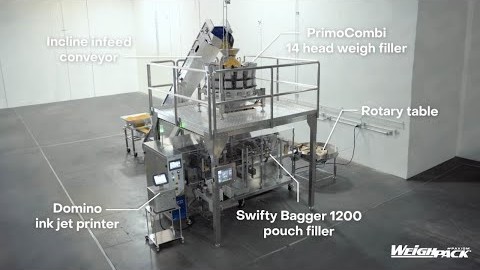

The Swifty Bagger 3600 and 1200 pouch filling machines for filling stand-up zipper pouches are engineered for medium to high production rates up to 2,400 bags per hour (higher speed servo model available).

Our unique straight-line design ensures the operator can see the entire bag opening, filling and sealing processes without the assistance of others, making it easier to operate, service and clean.

These machines include an easily accessible bag magazine to ensure every bag enters the machine square, an automatic zipper opening device, a bag shaker at the fill station for product leveling and an integrated exit conveyor.

The Swifty Bagger stand-up pouch machine can fill DOY pack, SUP and SURP pouches, pillow, gusseted, quad and carry handle.

For mechanical rates up to 2,700 bags per hour

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- AB MicroLogix PLC

- Color HMI

- Straight flow-through design

- Festo valves and vacuum generator

- Omron, Festo and SMC sensor

- No bag – no fill sensor

- Mechanical bag opening device

- Funnel clog sensor

- Heavy-duty cam shaft drive with encoder control

- Quick bag load station with vacuum mechanism

- Mechanical bag spreading station

- VFD variable speed control

- Integrated exit conveyor

- Encoder positioning logic

- 304 Stainless steel sheet metal exterior

*Rates subject to package style, type and size

-

Ideal Markets

-

Our Swifty Bagger 3600/1200 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.