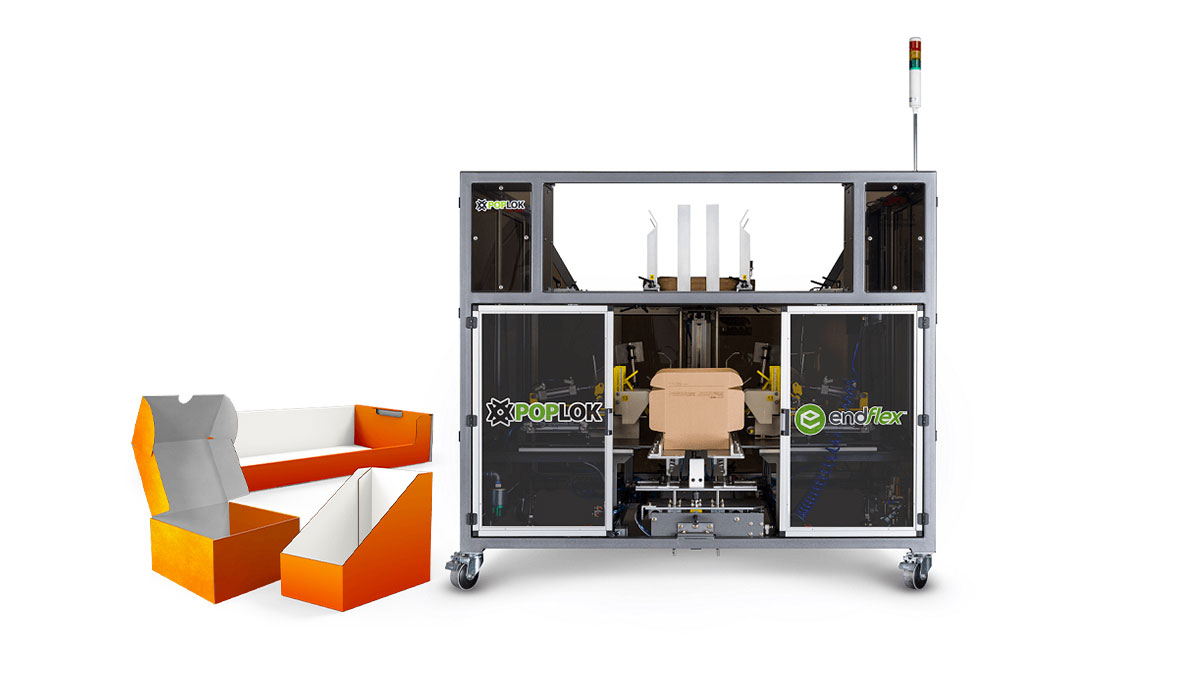

PopLok Tray Closer

Automatic Lidded Tray Closer

Fully automate your tray forming and packing processes with the PopLok tray closer, the ultimate solution for sealing lidded trays with unmatched precision and efficiency. The automatic incoming tray control gate ensures trays enter the system “short-side” leading, optimizing the sealing process. First, the tray dust flaps are folded 90 degrees and neatly tucked into the tray. As the tray moves to the next station, plow bars expertly guide the lid to a closed position. In the final steps, the front lip minor flaps are gracefully folded and securely tucked into front slots. The last compression station applies the perfect amount of pressure to seal the front flap with precision.

Videos

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

-

Ideal Markets

-

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

PopLok Tray Closer

Automatic Lidded Tray Closer

Videos

Fully automate your tray forming and packing processes with the PopLok tray closer, the ultimate solution for sealing lidded trays with unmatched precision and efficiency. The automatic incoming tray control gate ensures trays enter the system “short-side” leading, optimizing the sealing process. First, the tray dust flaps are folded 90 degrees and neatly tucked into the tray. As the tray moves to the next station, plow bars expertly guide the lid to a closed position. In the final steps, the front lip minor flaps are gracefully folded and securely tucked into front slots. The last compression station applies the perfect amount of pressure to seal the front flap with precision.

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

Features

- 1, 2, 3, 4 tuck or multi “fold & tuck” models available

- Form large or small trays with or without a lid

- No mandrel or tooling for quick tray size change-over

- Eliminate repetitive motion issues and insurance claims

- 100% recyclable trays—no glue and no tape

- Easy load hopper for tray blanks

- Heavy duty, welded steel frame

- Interlocked safety gates or doors

- Venturi vacuum technology used in tray erection

- Auto-idler

- Omron PLC

- Color touch screen allowing adjustment & full access to all functions & timing of machine

- Tray ejection system

- Central valve exhaust for noise reduction and clean air

- STEEL-IT paint with all moving parts painted bright yellow

- 24 VDC control voltage

- All electrical controls

- On-line detailed operation manual accessible through HMI

*Rates subject to package style, type and size

-

Ideal Markets

-

Our PopLoks are suited for all industries as your go to capping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.