BoxxPak

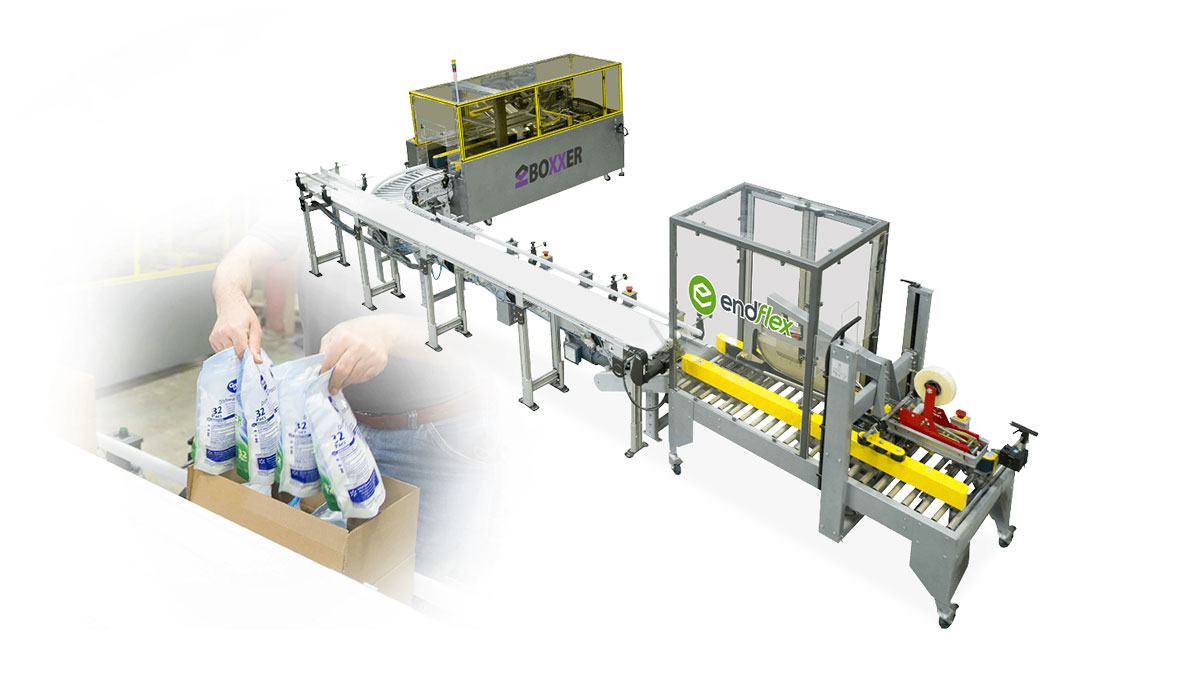

Automatic Case Erecting & Taping with Hand Load

The semiautomatic case packers combine case erecting, hand packing and tape sealing into a compact and efficient work cell. This ergonomically designed pick and pack system features an automatic indexing system that positions cases and products for optimal operator comfort, minimizing repetitive wrist and arm motions.

Be more efficient with the flexible BoxxPak case packing system! Stop the chaotic and inefficient case packing process from a rotary turntable and use the BoxxPak to increase production rates, reduce human loading errors, streamline your packaging process and improve operator satisfaction while reducing stress.

Videos

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer

*Rates subject to package style, type and size

Our BoxxPak is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer*Rates subject to package style, type and size

-

Ideal Markets

-

Our BoxxPak is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BoxxPak

Automatic Case Erecting & Taping with Hand Load

Videos

The semiautomatic case packers combine case erecting, hand packing and tape sealing into a compact and efficient work cell. This ergonomically designed pick and pack system features an automatic indexing system that positions cases and products for optimal operator comfort, minimizing repetitive wrist and arm motions.

Be more efficient with the flexible BoxxPak case packing system! Stop the chaotic and inefficient case packing process from a rotary turntable and use the BoxxPak to increase production rates, reduce human loading errors, streamline your packaging process and improve operator satisfaction while reducing stress.

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer

*Rates subject to package style, type and size

Our BoxxPak is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.

-

Specifications

-

How it works:

1. Automatically erect and form a corrugated case or tray

2. Convey incoming bags, pouches, cartons, containers, jugs, boxes or widgets to the staging area

3. Once product is staged, the operator will conveniently transfer the product from the conveyor into the case or tray

4. Once the incoming product is loaded per your pack pattern, the case will then be transferred to the sealing station and the process will be repeated

5. The top flaps of the corrugated case will be folded

6. Folded case flaps will then either be glued or taped

7. Voila! An automatically case packed finished product is ready to ship to your customer*Rates subject to package style, type and size

-

Ideal Markets

-

Our BoxxPak is suited for all industries as your go to tray forming machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

- Vegetable

and many more industry applications.