By George Guidoni, Editor

Photos by David Buzzard

or a legal industry barely four years in the making, Canadian producers of recreational cannabis products are quickly finding out that simply getting a license was never going to be a license to print money without lifting a finger.

And with the industry’s early growing pains further exacerbated by the prolonged outbreak of the COVID-19 pandemic, it’s safe to say that many of the early high expectations of Canada’s cannabis sector becoming an overnight juggernaut with endless financial windfalls were based on a lot of wishful thinking.

That said, there is no doubt that the industry is now entering a critical stage of its accelerated evolutionary process—rewarding serious players committed to helping the market grow to its full potential and weeding out wannabe charlatans and opportunists hoping for a quick and easy payday.

Headquartered in the heart of the famed Okanagan Valley in Kelowna, B.C., The Valens Company certainly falls into the ranks of true industry leaders, not only in terms of sales and market share growth, but also in the science and technology of cannabis production—with packaging very much included.

Founded in 2012, Valens has quickly emerged as an industry leader under the leadership of its founding chief executive officer Tyler Robson. Blessed with a unique skill set and valuable contacts with other industry professionals, Robson has worked tirelessly to assemble a seasoned management team with extensive experience in cannabis production.

Operating as a cannabis LP (licensed producer), Valens currently ranks as one of Canada’s top 10 producers of recreational cannabis products, with about a 3.5-percent share of the Canadian market. “The Valens Company is a leading manufacturer of cannabis products with a mission to bring the benefits of cannabis to the world,” says Valens director of technical development and innovation Anastasia Reyes.

“We provide proprietary cannabis processing services, in addition to best-in-class product development, manufacturing, and commercialization of cannabis consumer packaged goods,” says Reyes, an Alberta native who moved to Kelowna to join Valens in 2021 after supporting the construction and license submission of an LP in her home province to complete a personal move “from oil-and-gas to oil-and-grass,” she quips.

“Like anything new, the cannabis market has seen its challenges,” Reyes says, “but it’s still exciting to be a part of what future generations will call “The Great Green Rush.’

“We are all pioneers of the industry, finding new ways to focus on our executive teams’ drive to be ‘fewer, bigger and better’.”

The lion’s share of the company’s flower processing and production takes place at its modern, spanking-clean 100,000-square-foot Agritech manufacturing compound in Kelowna, which employs over 125 people on a three-shift production schedule to manufacture cannabis products for the company’s own brands and for its many “white label” customers, according to Reyes.

“Our state-of-the-art facility has allowed us to master diverse extraction methods, and develop in all categories of the Canadian market, including flower, vapes, extracts, edibles, beverages and topicals,” Reyes explains.

“We can fully support the progression of product from flower to retail shelves,” says Reyes, adding that all of the company’s branded products are available across Canada.

According to Reyes, the opening of the Agritech plant in Kelowna has been welcomed with open arms by the local business community and municipal politicians for its positive local economic impact and job creation in Kelowna, where Valens also has a purpose-built edibles facility, along with Valens Labs Centre of Excellence in Plant-Based Science to offer third-party testing services as required by Health Canada.

“Rooted in the Okanagan, we pull from the local history of agriculture in the industrial era to the modern-day end of prohibition to create cannabis with purpose, backed by science,” Reyes states.

Also operating a newly commissioned, purpose-built plant to produce cannabis-infused beverages in Bolton, Ont., Valens clearly has its eye on the future with its comprehensive and wide-ranging portfolio of high-quality cannabis products spanning most common product types, consumption methods and potency levels.

“Formulated for the recreational, health-and-wellness and medical consumer segments, our high-quality products are offered across all cannabis product categories— with a focus on quality and innovation,” Reyes states.

“Working in partnership with brand houses, CPG (consumer packaged goods) companies and licensed cannabis producers around the globe, The Valens Company is continuing to grow its diverse product portfolio in alignment with evolving cannabis consumer preferences in key markets,” she relates.

“We hit the market as one the first and best in class extraction facilities and continue to do so in CO2, ethanol, and hydrocarbon facets,” she adds.

“Our portfolio has expanded to allow our facility to house cutting edge equipment to produce consumer package goods in all categories of the market.”

Despite the growth in extraction categories, dry flower cannabis remains the dominant product in the Canadian recreational cannabis markets with about an 86-percent share of all sales, according to Reyes, with sales of pre-rolled cones (joints) accounting for a large majority of that total.

As Reyes relates, Valens has achieved significant success in this market segment with its four core flagship brands that include Contraband, Versus, Citizen Stash, Vacay, and the newly launched Bon Jak label for the Quebec market.

“Our Versus God Bud ranked as the Number One bestselling SKU (stock-keeping unit) for four consecutive months in 2022 amongst all product categories in Ontario, Alberta, British Columbia and Saskatchewan,” Reyes confides.

“We also have the ability to support our partners in all formats—providing products in bulk to complete ‘white label’ solutions.”

As many recreational cannabis startups in Canada have struggled to turn a profit on a regular basis, Reyes says that many industry newcomers had failed to realize the extent to which they would have to automate their existing manual-intensive processes to achieve profitability.

This is especially true in the market for pre-rolls, where many companies still rely on outdated manual techniques or using rudimentary tabletop technologies to produce their pre-rolls.

“One of the main challenges this industry presents is that the security and quality control of producing compliant products comes with a price,” says Reyes.

“Not only are we subject to excise duty of approximately $1 per gram of dried flower, but a manufacturer has significant overhead in security equipment and additional personnel needs.

“So even as we are actively striving to lower manufacturing costs, we have additional fixed levies and labor costs on cannabis products that other CPG (consumer packaged goods) industries are not constrained with,” says Reyes.

Hence profitability is directly linked to how well manufacturers manage to slash their operating costs, she says, with labor being one of the main culprits.

As Reyes relates, that has not been a problem with the Agritech plant’s preroll production ever since the company installed and started up a fully-automatic JuanaRoll pre-roll system in December of 2021—essentially automating the entire pre-roll production process and vastly expanding its manufacturing throughput, capacity and productivity levels.

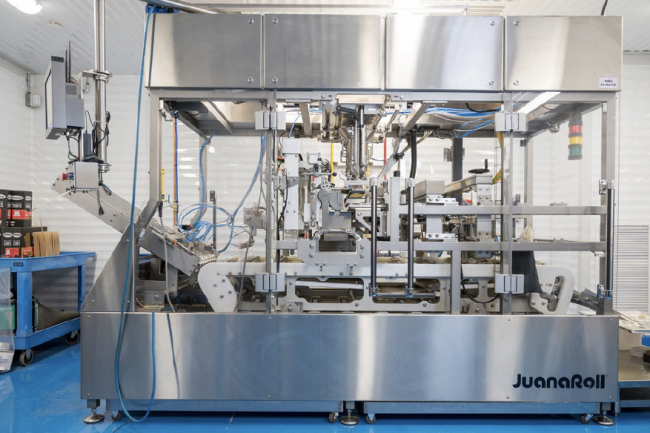

Manufactured by renowned Canadian packaging machinery manufacturer WeighPack Systems in Montreal, the highly innovative JuanaRoll automatic pre-roll machine was developed as an automated solution to replace manual hand-rolling of pre-rolls with a fully-automatic process delivering high-precision weighing accuracy and consistent product quality and uniformity at breathtaking speeds.

Manufactured by renowned Canadian packaging machinery manufacturer WeighPack Systems in Montreal, the highly innovative JuanaRoll automatic pre-roll machine was developed as an automated solution to replace manual hand-rolling of pre-rolls with a fully-automatic process delivering high-precision weighing accuracy and consistent product quality and uniformity at breathtaking speeds.

Available in four-, six- and eight-channel configurations, the high-speed JuanaRoll machine features an easy-to-load cone magazine, an integrated PreCheQ checkweigher, and special stations for compacting, tamping and twisting/trimming, along with value-added standard features such as no-cone/no-fill detection, cone-open camera vision system, and free online technical support.

Installed in an eight-channel version at the Agritech plant, the JuanaRoll has performed with remarkable reliability and flexibility, according to Reyes, producing up to 65 perfectly made cones per minute—ranging from 0.35-gram to two grams—in continuous operation.

Says Reyes: “I had the privilege of previously working with the WeighPack group before moving to Valens, so when I began facing the challenges of a rapidly growing and evolving industry, I knew exactly who to call on.

“Their knowledge of manufacturing equipment, and focus on manufacturing efficiencies, helps to create specifications for not just equipment but for supporting an entire process,” says Reyes, complimenting the JuanaRoll machine’s linear modular design that allows it to make pre-rolls simultaneously in up to eight lanes, rather than the one-at-a-time preroll production offered by standard rotary- design pre-roll systems.

“WeighPack offered us full support throughout the project: from the equipment specification phase straight through to pre-arrival room requirements, installation qualifications, and performance verifications, with onsite support for training and real-time troubleshooting,” Reyes recalls.

“They also provided detailed vendor manuals, checklists and an access portal help to ensure we have support while we’re running through all three shifts: days, nights and weekends.

“It’s been a fantastic investment from Day One,” Reyes extols. “It hasn’t even been a year, but it feels like it’s been here forever. It has taken our pre-roll productivity to a whole new level of excellence.

“It’s not just the impressive speed,” Reyes points out, “but also the product weight consistency and quality, which we have to maintain within Health Canada’s strict tolerances.

“So it has been a real game-changer for us.”

Says Reyes: “Since legalization the Canadian consumer has become more discerning—giving LPs the chance to bring even better products to the market, but still needing to compete with the diversity and pricing of the legacy [black] market.

“As the legal cannabis industry has evolved in Canada, it has become clear that key success criteria in this business is based on being a good CPG manufacturer, which often means investing in automation to reduce operating and labor costs to remain competitive.

“That’s what we have done with our pre-roll production with the JuanaRoll installation,” Reyes says, “and we are not stopping there.

“That’s what we have done with our pre-roll production with the JuanaRoll installation,” Reyes says, “and we are not stopping there.

“Our product portfolio has expanded to allow all our facilities to house cutting-edge consumer packaged goods in all categories of the market,” she sums up, “and having cracked the Top Ten flower producers list, it is now our intention to become a Top Five producer in all categories.

“And as we pursue our goals, we will continue working with Health Canada to uncover new market opportunities and to continue bringing safe, high-quality and consistent cannabis products to Canadian consumers.”