Packaging Equipment Machines in British Columbia

As the province that has the mildest climate in Canada, British Columbia offers an impressive selection of things to do and places to check out. Whether you’re into exploring cities, soaking up nature through mountains, just lazing around oceans or anything in-between, you can all find that in British Columbia. Ever tried mountain biking on an actual mountain? Go to Sun Peaks Resort then, which also features a mountain that can only be accessed by lifts. Don’t worry, the mountain biking trail is designed for beginners.

For some rugged and scenic views, head over to Yoho National Park. It features rivers, clear lakes, waterfalls, and snow-capped peaks. The beautiful Lake O’Hara is also located in this park. Another popular destination, specifically during summer, is the Okanagan Valley where you can see people enjoying the beach, houseboats, and golf. Vancouver is a widely known city in Canada and one of the reasons for this is its Stanley Park. Located on the edge of the downtown core, this wide green space makes a perfect retreat for anyone who’s into jogging, biking, or walking. There are also trails in the forest and the Vancouver Aquarium within the park.

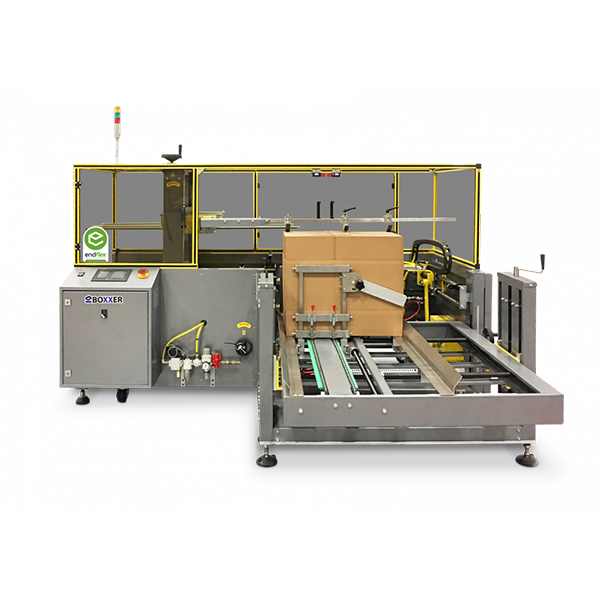

T12 case erector with tape

Why use tape case sealers

Things like increasing labor costs, the urgent need for faster production lines, and high employee turnover are driving warehouses and facilities to automate. And when it comes to end-of-line automation, it requires careful planning and consideration as this investment can either make or break your production line. For businesses that need to save more, using an automated case sealer may seem like the last thing they need. To give you a better understanding of the role of case sealers on a packaging line, here are the top benefits of this packaging machinery:

Provides higher outputs

The line, “Doing more with less” best describes tape case sealers. By using these machines at the end of your line, sealing cases are done at much faster rates. Compared to having many workers to do it, you can easily use a case sealer or two to automate this process while increasing your production output.

Eliminates the need to double-tape

A case sealer uses a single strip of tape to seal the case, thus, removing the need to reapply tapes across the container. With a case sealer, you can ensure complete and consistent closure while using less tape.

Eliminates uneven tape lengths and placements

An automated case sealing packaging machinery also works to regulate the length and position of the tape on every carton. As a result, it eliminates excess tape that is typically found in many boxes these days.

Improves packaging appearance

Over-taped cases reduce the aesthetics of the cases. But through a case sealer, you won’t have to worry about this. Instead, you’ll be getting more professional-looking cases.

Better product security

The higher the consistency, the better the security. A case with a single tape strip when tampered can be easily detected than a carton that has several, overlapping strips of tape.

Reduces product damage

Other sealing materials like staples, straps, or glue put your products or workers to higher risks than when using tape. Moreover, sealing machines that use glue or staples usually require higher maintenance costs than automated tape case sealers.

Minimizes employee injuries and downtime.

Repetitive motions incurred at manual labor cause body harm to employees. By automating your case sealing process, you are removing the chances of employee fatigue, injuries, and downtime. In other words, it would be less headache for your management team.

EZ-Tape series to automate your case sealing process

At Paxiom, we engineer a variety of case sealing machines. We have case erectors that also work as case sealers and we also have standalone case sealers. Since we are talking about case sealing, we will be focusing on our EZ-Tape family of case sealing packaging machinery. Our EZ Tape machines are designed to take your erected box filled with products then seal either the top, bottom, or sides of the case. By having an automated sealing process, you can significantly increase your productivity while also minimizing manual repetitive labor.

EZ Tape CS-A50

Equipped with dual masts, the A50 case sealer ensures a stable sealing of the bottom and/or top part(s) of the case. The entire unit’s height can also be adjusted accordingly.

EZ Tape CS-C50

This uniform case closer and sealer has robust side-belt drives and tool-less tape heads. You can use it as a standalone sealer or as part of your existing production line.

EZ Tape CS-150

Engineered with ease of use and flexibility in mind, this tape case sealer offers quick changeover and is built with an easy-to-load tape cartridge. Like the other EZ Tape models, it also comes with heavy-duty side-belt drives and casters.