Delaware Packing Systems

Despite getting the nickname “The First State” as the very first state to be on board with the United States Constitution, Delaware is not much bigger than Anchorage, Alaska. What’s more, its total population is less than a million. As such, it’s not much of a surprise how the state is at a shorter end of the stick when it comes to the rest of the country’s appreciation for it. Nonetheless, the state of Delaware has its fair share of attractions and spots to explore and get lost on.

Located on a lush 1,000 acres of green meadows and beautiful woodlands are Winterthur Museum, Garden, and Library. The house and its wide grounds are open for visitors where they can enjoy the beautiful garden. Another place you can visit is the Bellevue State Park. In there, you can find hiking trails, a fitness track, tennis courts, and a fishing pond. It’s also a good place to have a picnic or to stay by renting one of the indoor spaces available. For a quiet afternoon escape, check out the Delaware beaches where you can enjoy various water sports, especially at Rehoboth beach.

Paxiom for your check weighing needs

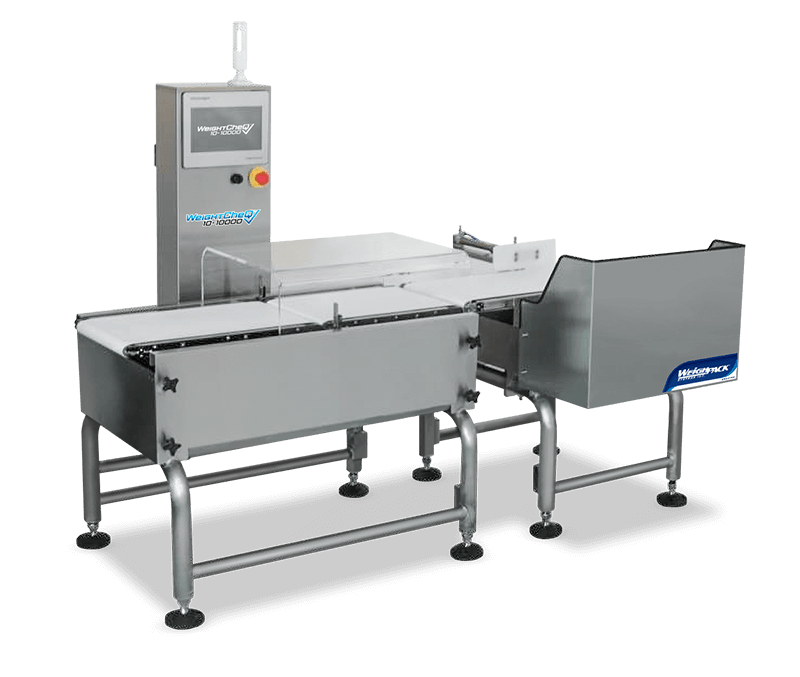

At Paxiom Group, we provide a wide plethora of automated packaging machinery for various technologies. One of those is our auxiliary product line that consists of labeling, capping & unscrambling, and our new addition, check-weighing. Our WeightCheQ is an automatic packaging machine that check-weighs your packages, cases, bags, bottles, cartons, and many more, all the while offering simple operation, accuracy, and speed. The WeightCheQ is designed to be easily integrated into any current packaging system, be it container filling, case filling, flow wrapping, and automatic bagging.

Features of WeightCheQ

- Robust and durable 304 stainless steel frame

- Dynamic weight tracking that features automatic compensation to enhance stability

- CNC machining of structural parts to ensure a great dynamic stability

- An operator-friendly user interface

- Fast-speed response thanks to its high-speed load cell

- Product presets that are simple to modify and change

- A weighing history query and USB export option for easier data management

- Weighing parameter controls coupled with smart self-learning function

Our WeightCheQ packaging machinery comes in three models:

1. WeightCheQ 3-1000 with a weighing range of 3 to 1000 grams

2. WeightCheQ 10-4000 with a weighing range of 3 to 4000 grams

3. WeightChecQ 10-100000 with a weighing range of 10 to 10000 grams

Understanding check weigher packaging machinery

The manufacturing industry pays close attention to quality control, possibly more than anything else. At every production stage, it’s crucial to ensure that the ingredients or materials match the required standards, even more so when it comes to quantity. Therefore, weighing scales are an essential tool. A check weigher is a specific type of weighing scale that’s used in many industrial applications.

Without this piece of packaging equipment, products that don’t meet the quantity requirements can easily pass through the production and eventually reach retail stores. Such inconsistencies will be harmful to any company and could result in the products being recalled. It won’t just be money they’ll lose, but also the hard-built good reputation. A check weighing machine helps ensure that the product’s volume is as exactly as it says in the label.

In general, check weighers are commonly seen in the different production stages of manufacturing companies. Whether it’s to measure individual components or to package the final product, these weighing scales are of great importance. Food production industries, in particular, acknowledge the huge role of these tools, mainly due to the stringent quality standards. Food industries aside, check weighing packaging machinery is also used in several industrial applications. Suffice it to say, with the help of check weighing machines, any business can successfully meet their production and quality control requirements.

Uses of a check weigher

- Confirm the number of products in a carton by determining if it lacks a piece or component

- Spot underfilled or overfilled product packages

- Cuts back product recalls and other quality-related problems

- Comply with FDA regulations and industry specifics on product quantity

- Arrange products according to weight

When choosing which check weigher to buy, it’s important to consider the scale brand. Research about the scale manufacturer first to see if it’s reputable and reliable. Some packaging manufacturers provide a warranty and offer repairs and maintenance. Also, these days, electronic weighing scales are often preferred by some industries. Still, it’s important to also consider that some applications need manual readouts and functions.