Packaging Machines for Illinois Companies

Everyone knows which city is the most popular in the state of Illinois–and it’s no other than Chicago. And while this Windy City does have so much to offer, it isn’t the start and end of Illinois, either. Known as the Prairie State, this US state is an amazing place for museum lovers and history buffs. But if you’re looking for a place to spice up your trip, then you may find Cairo interesting, and by interesting, we mean, spooky. The historic downtown of Cairo is seated on the intersection of the Ohio and Mississippi rivers. This eerie ghost town is a worthwhile stop if you want to experience something entirely new.

Moving on to the top attractions of the state, Discovery Center Museum holds more than 300 hands-on arts and science exhibits, with a play area and planetarium that will surely be a paradise for kids. Another must-visit attraction is the 360 Chicago, an observatory that’s on the 94th floor of a skyscraper, John Hancock Center. The observatory lets you see a panoramic and splendid view of the city. If you’re lucky and the day is clear, you can see up to 4 states from the observatory. It also includes a free interactive tour–you might want to take on that offer.

What’s a cartoning machine?

A cartoner, or cartoning machine, as its name suggests, is a type of packaging machine that forms cartons. Cartoning machines can be categorized into two main types: vertical cartoners and horizontal cartoners. But, how does a carton machine work in the first place?

First, the carton machine picks up one piece of carton blank from the stack of blanks then positions it to stand up straight or erect. Through the open end of the carton, the machine fills it with products horizontally, then closes it by either tucking the end flap or sealing it with glue or tape. The process of cartoning isn’t that hard to imagine, but for people who aren’t in the packaging field, it’s common to feel confused since they haven’t seen the process live. Depending on the carton packaging machine, the product can be pushed into the carton with either a mechanical sleeve or pressurized air. Technology doesn’t stop evolving, so there’ll always be new ways of doing things. Nonetheless, for many applications, the products are commonly loaded into the carton manually, meaning, by hand.

Introducing the Vertical Cartoning Machine from Paxiom

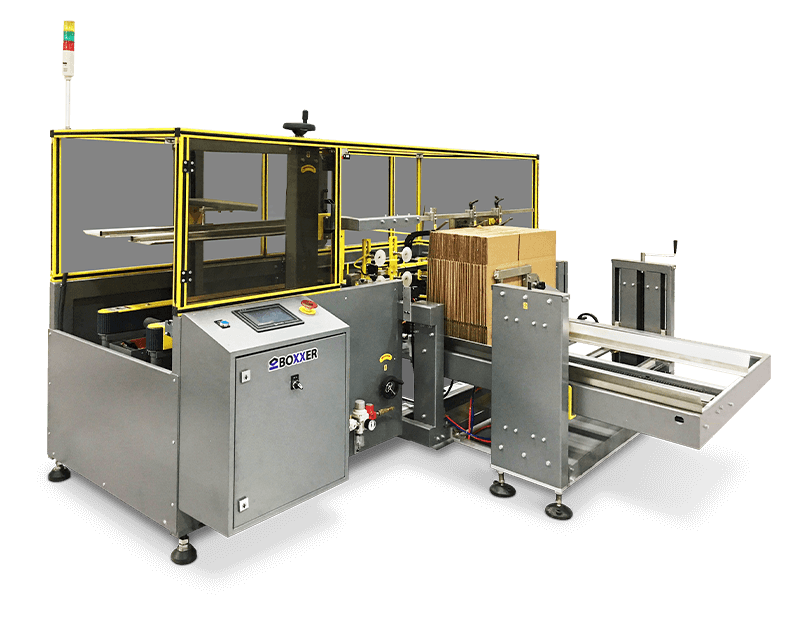

Coming from the Boxxer line, which is under the EndFlex brand, we at Paxiom are proud to introduce our very own automatic Boxxer Kartnr vertical cartoning machine. This packaging machine for cartons is designed to assemble and tuck & close cartons on chipboard-style. It’s completely versatile, thus, can handle auto-lock cartons, glued cartons or handle tucked cartons. Whether you want a manual loading or an automatic one, our Boxxer Kartnr packaging machinery has you covered.

Manufactured in 2 models, we have:

- Boxxer Kartnr Automatic can include an infeed conveying system to automatically collect products and fill them directly to the carton to eliminate human labor

- Boxxer Kartnr Hand Load is a vertical cartoner that automatically opens and moves the carton to the filling area where a person is waiting to load its contents. After loading, the top cover of the carton can either be automatically tucked or sealed with glue or be left open.

Vertical cartoners vs horizontal cartoners

With vertical cartoning machines, the carton is loaded vertically in the machine, and the product is inserted either automatically or by hand, most often from the top of the cartoner. Meanwhile, horizontal cartoning machines involve inserting the product from the side of the carton. This type of packaging machinery can run in intermittent or continuous mode, with options like automatic lateral product loading and glue or flap insertion closure. A vertical cartoner is perfect for packaging bare products (e.g., rice and dry pasta) that must or can be supplied by gravity and are sold by volume or weight. On the flip side, a horizontal cartoner is normally used in packaging food products like pizza, cake, or vacuum-packed rice.

When choosing which vertical or horizontal cartoner to purchase, it’s important to carefully consider some factors. For instance, you will want to have a packaging machine with a robust design that can survive the degree of your production environment. The cartoner must also be customizable and versatile enough to meet your existing and future packaging needs and standards. Additionally, manufacturer experience and industry reputation are also essential factors.