Packaging Systems for Rhode Island Companies

Although the smallest state in the United States, this obviously didn’t hinder Rhode Island from bravely declaring its independence from Great Britain many decades ago. Its strong culture and character are more than enough to make up for its size. With over 400 miles of coastline, multiple lavish mansions, quirky but tasty culinary treats, and so much more, it’s time for Rhode Island to be included on any traveler’s visit list. Experience the gleaming, highly-celebrated event called WaterFire Providence during May and October at downtown Providence. This attraction is very popular in North America. Oh, and stop by at Pastiche, too, so you can try some of the most delicious foods in Providence.

Another great attraction is the Rosecliff Mansion in Newport with its grand architecture and decor that’ll make you feel like you’ve stepped into Newport history. And while you’re at Newport, you can also visit other grandiose mansions like the Hunter House, Marble House, and the Breakers. For nature lovers and bird enthusiasts, in particular, you’d love the Norman Bird Sanctuary in Middletown. It’s home to dozens of bird species and other local wildlife. There are also expansive grounds and trails to explore to satisfy your adventurous soul.

Side Case Packers-what is it?

First off, a case packer can be classified into several types, such as wraparound packers, rotary packers, top load packers, bottom load packers, and many more. With a side case packer, it’s commonly used for boxed items such as bars of soap or dry pasta since these products are easier to push on the side than top-loading them. In general, side load packers can finish up to 20 cases per minute, as opposed to other types that have relatively higher mechanical ratings.

Paxiom offers side load case packing solutions

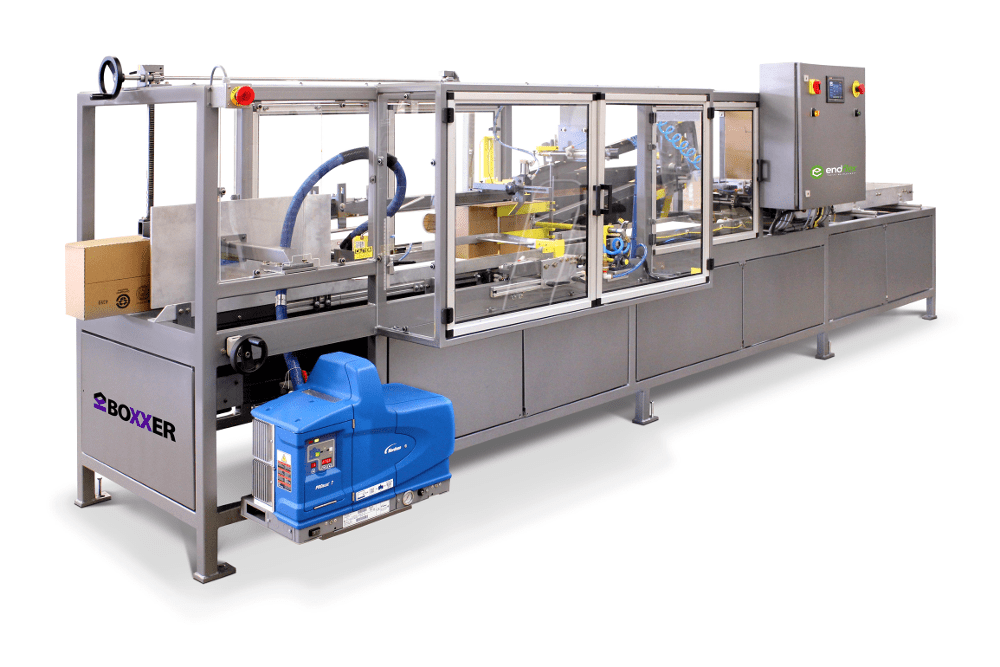

We manufacture a wide selection of side load case packers that automatically load your bottles, cartons, and containers filled with products into corrugated cases. Sideloading is often used for high packing applications as well as careful handling of products. Through our Boxxer case packer, you can automatically case pack your finished products with ease and accuracy so they’re ready to be shipped to your customers.

How it works

Our Boxxer All-in-One Side Loader packaging machines are all equipped with servo drives to provide efficient and consistent side loading. To start with, the products are fed to the side load packer through an infeed conveyor. Second, they are collated and arranged as per your preferred pack pattern so they can be loaded into the case accordingly. Once the product staging is complete, the products are now prepared to be inserted from the side of the corrugated case. Meanwhile, the case is taken from the blank hopper then assembled near the awaiting products.

The case is opened so the guides can enter first before the products are loaded using the servo-drive side-load mechanism. To finish it off, the case flaps are folded then the case is forwarded to the side belt conveyors to seal it with either glue or tape. Lastly, the flaps are compressed while the case passes by the remaining stage of the machine before it can be discharged from the side packer.

So, to sum it up, a side loading process consists of four major steps:

1) Product collating, 2) Product staging, 3) Case erecting, and 4) Case seal and discharge.

Our Boxxer Side Load Case Packing Machines are equipped with notable user and service features.

Designed with the operator in mind, these case packers make use of an easy-to-load blank magazine that allows blanks to be fed continuously so there won’t be a need to stop the former. Another useful feature is the convenient location of the sealing system (glue or tape), which makes it easier to replenish. And of course, we have engineered our case packers with a user-friendly color touch screen.

For the service features, we have three. First is the interlocked doors. Our side case packers simplify the maintenance process with their highly accessible machine parts. Another one is the presence of SMC pneumatic components to allow convenient preventative maintenance. And lastly, we have also engineered these packaging machines with NEMA control panels to allow reliable and safe operation. Other important features include low/no product sensors, quick size changeover, case erector, color touchscreen user interface, wide tape head/glue system, interlocked safety doors, low hopper alarm, Venturi vacuum, light stack, and servo loading mechanism.