Packaging Machine Systems in South Dakota

South Dakota is a well-rounded destination for every traveler. Interestingly, this state has many fascinating surroundings. People may see it as a boring state filled with farmland and prairies, but there are far more beautiful attractions in South Dakota. Have you ever heard or seen a picture of a monument of four great American presidents set in the mountain? You can find it in Mount Rushmore. The sculpture is the king of attractions in this state, bringing millions of tourists yearly. Located in the Black Hills is the Bear Country USA, an animal park that’s home to many North American mammals like black bear, buffalo cougars, bighorn, bobcats, and so much more.

Surround yourself with rich agricultural land and abundant food scenes in Sioux Falls. The place doesn’t conform to the latest trend and it’s a perfect place to get farm-fresh foods. Check out The Market, a restaurant-slash-grocery store where you can try creating your own cheese boards and charcuterie. For a beautiful drive, go to The Needles Highway situated within Custer State Park. This 14-mile long drive lets you savor the mountain vistas and rocky outcrops. Want to see wild mustangs running free? Head over to The Black Hills Wild Horse Sanctuary, an 11,000-acre that houses 600 mustangs where they just roam free all day.

What is end-of-line automation

End-of-line is a case packaging automation that allows major manufacturers across the globe to reduce unnecessary, frivolous expenses, and material expenses. This automated packaging machinery is placed at the end of a production line that works to package the newly manufactured product ready for retail consumption. Various types of automation can be used as part of the end-of-line solution. Some of these are box/bag filling machines, box/carton assembly machines, palletizing systems, box and bag sealers, and labeling and inkjet printing.

Why use end-of-line technology

This packaging technology also eliminates the risk of human error and optimizes packaging materials used in the operation. To know more about packaging automation, let’s take a closer at its effect on the following aspects of packaging:

1.Labor needs

With automation, employees who are manually filling boxes can be assigned to more essential tasks, reducing the need for human resources and lowering the cost of finished goods. As a result, it boosts your company’s ability to compete with other manufacturers, thus, improving your overall profit margin. By automating your end-of-line packaging, you can put valuable labor hours to other areas in your operations where they will be utilized fully.

2.Financial gains

Needless to say, optimizing your workers’ labor time means more savings for you since those hours can be better spent on other aspects of the production line. Case packing automation eliminates tedious manual packaging procedures to completely replace them with a labor-free (and more efficient) method. Moreover, automation cuts back a significant amount in the material used since it maximizes your material, resulting in little to no inefficient packaging mishaps.

3.Varying solutions

Of course, for production lines that only require less than 10 cases per minute, using full automation isn’t the best idea. This is where semi-automatic packaging machines come, as they deliver the same labor and savings material as fully automatic machines. Furthermore, aside from the level of automation, case packing solutions can also cater to unique industries and production systems.

Today, case packers come in different types including top-load, side-load, bottom-load, and drop case packing systems).

Paxiom provides a wide range of end-of-line solutions

As one of the most sought brands when it comes to packaging machines, Paxiom has made sure that all its machinery and equipment are designed meticulously and perfectly by their engineering team. Such solutions are expected to provide its users with reduced labor and increased productivity and bottom line.

Carton Former with Inserter

Designed to take one tray blank at a time, this carton forming machine is equipped with hopper and forming flows for effective erecting of the tray and folding of the flaps. Its main function is to load insert to the trays.

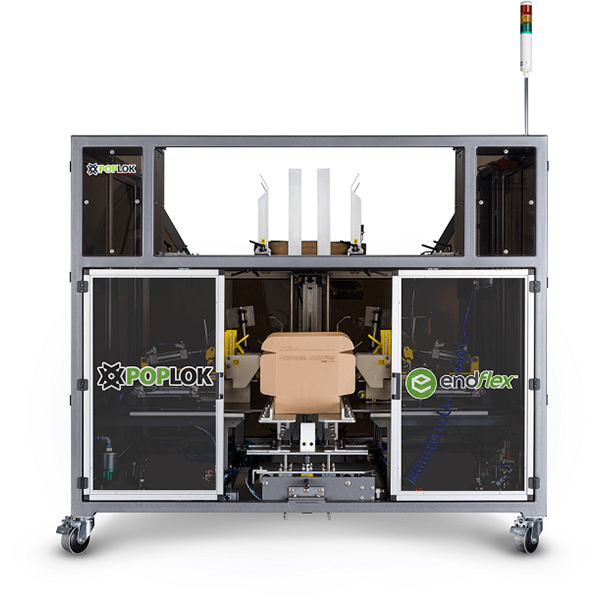

Case Erecting and Tray Forming

Our tray former comes from the PopLok and Vassoyo brand. Meanwhile, we also have the Boxxer product line, which consists of automatic case erectors for tape.

Case Packing and Palletizing

Engineered to accommodate your specific application needs, our case packing systems utilize the pick and place robotic technology to drop-pack and case up-stack your cartons.

Vertical Cartoners

Lastly, we have the latest addition to your end-of-line solutions, which is an automatic vertical cartoner that handles tuck and close chipboard cartons. This packaging machine can be used automatically or through hand-loading.