Packaging Machine Systems in Yukon

Yukon is a Canadian territory that’s rich with natural, historical, and cultural sites. It’s one of those places that makes you fall in love in a heartbeat. Pitch a tent in the pristine wilderness of Tombstone Territorial Park where you can see gorgeous mountain and lake views. It’s a great place to disconnect from your modern life and just be around nature. If you’re in Yukon anytime in late August and early April, you’d likely see the northern lights especially if you’re at the Inn on the Lake. The inn also has various summer and winter activities for its guests.

Then two hours south of Whitehorse is Carcoss with its cluster of vibrant houses and shops to celebrate the First Nations people. It’s an interesting place to be at, so you might want to pay this a visit. For lots of wildlife action, check out the Yukon Wildlife Preserve, a viewing property with over 700 acres of land consisting of several natural habitats. You can explore the area on foot or take a guided bus tour. Uncommon animals like woodland caribou, mule deer, wood bison, Dall’s sheep, and an arctic fox can be seen on this preserve.

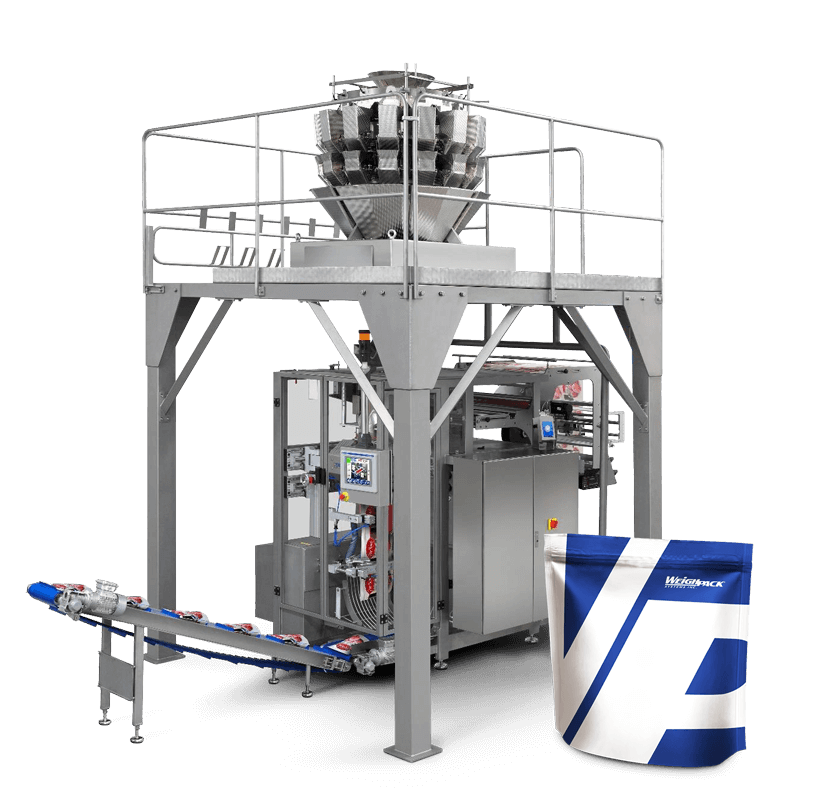

How vertical FFS machines benefit your Yukon business

Vertical form-fill-seal machines have become a staple to many packaging lines these days, which isn’t exactly surprising. These packaging machines are commonly used in the food industry and other products as well. Vertical FFS machines create plastic pouches using a roll of plastic film then simultaneously fill the pouches with products and seal them. Also known as VFFS machines for short, they are incredibly versatile and are capable of handling solids and liquids.

Aside from their efficient and high-speed performance, VFFS packaging machines are capable of finishing dozens of packages per minute while maintaining high consistency with each package having the same amount of content on it. Many food packages can be filled with nitrogen to extend the product’s shelf life. At Paxiom, our vertical FFS machines can be configured to use this specific function, all the while offering ease of use and flexibility. Our vertical packaging machines come in three models: the VerTek series, the XPdius series, and the latest addition, DoyPack-XP.

VerTek 800 and 1200

These cost-efficient models of VFFS machines can create pillow bags or gusseted bags sizes of up to 8 inches wide for VerTek 800 and up to 12 inches wide for VerTek 1200. As for their mechanical ratings, the Vertek 800 has a maximum of 60 cycles per minute while VerTek 1200 has a speed of up to 50 cycles per minute. Our VerTek family of vertical form-fill-seal machines is engineered for simple cleaning and servicing.

XPdius 130

Available with a gas flushing option, the XPdius vertical machine can accommodate a diverse range of products while displaying high speed and great serviceability. Its production rate can go up to 100 bags per minute. This packaging machine is equipped with servo motors to provide control over positioning and overall production. Other important features include horizontal seal jaws, HMI color touchscreen, and several filling options like filling below the jaws, above the jaws, and as the film pulls.

DOYPACK-XP

Designed with a small footprint, our newest vertical FFS machine is capable of forming high-quality stand-up, doy packages. Like the other VFFS machines of ours, this one also uses flat roll stock to create up to 55 bags per minute. You can opt to have a zipper enclosure included or not. Finished bag sizes are 4-7 inches to 11 inches wide and 6.7 inches to 11 inches long.

How they work

VFFS machines provide businesses an efficient and fast way of packaging their products. A machine is loaded with a roll of plastic film and the outer edges are sealed together to form the pouches. Then a sealing bar is activated to clamp the bottom part of the plastic, sealing those pieces together. The pouch is placed onto the weighing table so the product can be filled into the pouch.

Once the target weight of the pouch is achieved, the product filling process stops then the sealing bar sealers the top of the pouch. From there, the pouch is cut to separate it from the rest of the roll film. VFFS machines can also be configured to fill the pouches with air from an inert gas supply. This process occurs during the sealing process. It is done to protect the product from crushing and to drive out oxygen that, to curb or slow bacteria growth.