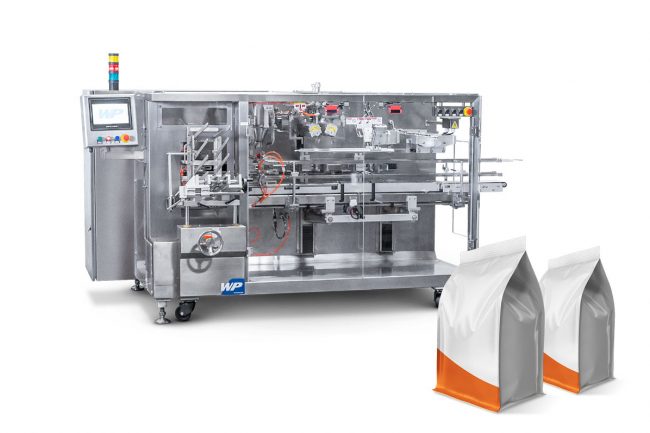

We’ve engineered the perfect bagging system for your premade box gusset bags.

Engineered for one of our clients in the coffee industry, this system is the perfect solution for packaging coffee and other powder or granule products. But it will also efficiently bag other products where a box gusset bag is needed, such as candy, nuts, baked and dry foods, jerky or even hardware and textiles.

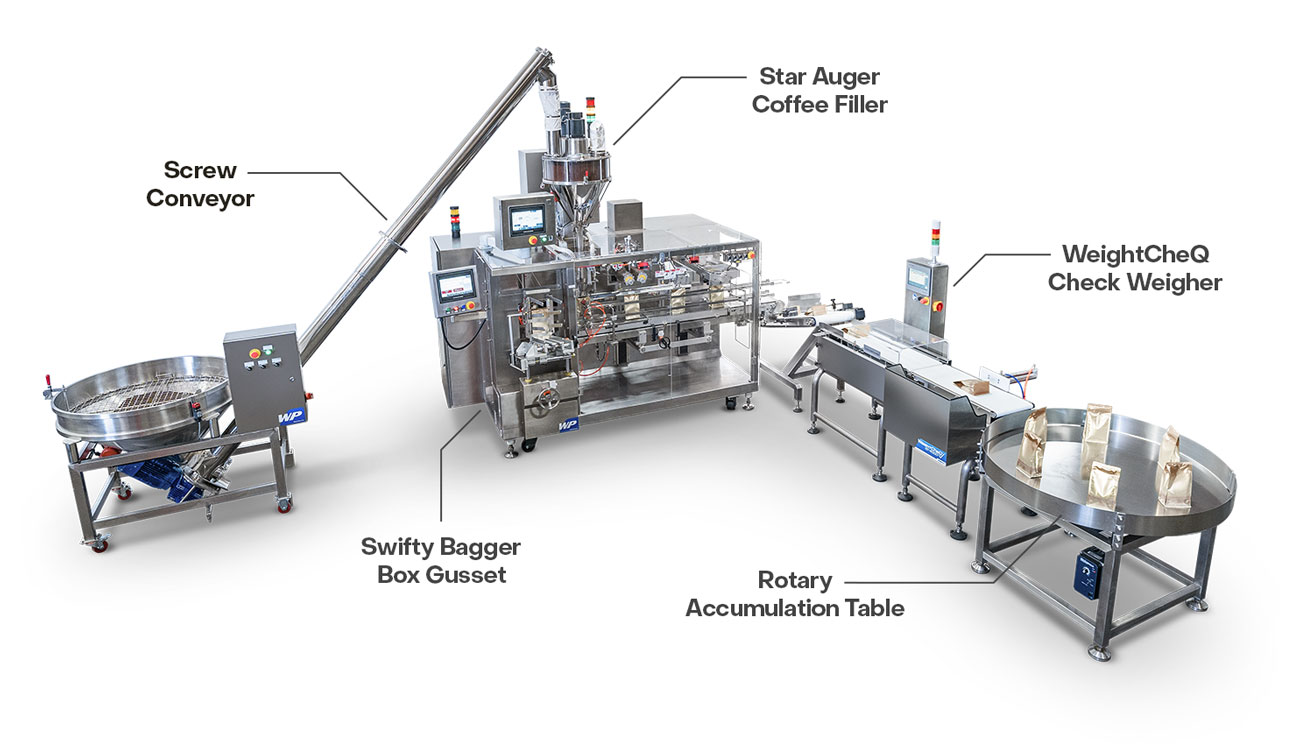

For our coffee client, we designed this automated system to convey their ground coffee from a hopper up to our Star Auger powder weigher using a screw conveyor.

For our coffee client, we designed this automated system to convey their ground coffee from a hopper up to our Star Auger powder weigher using a screw conveyor.

Once weighed, it passes into our Swifty Bagger Box Gusset bagging machine where it’s filled into gusseted premade bags before the sides are tucked and the top is sealed. To ensure the coffee properly settled into the bag prior to sealing, we included an integrated bag shaker.

We then convey the bags to our WeightCheQ check weigher where each bag is checked to make sure it meets the preset weight tolerance before it is accumulated on a rotary table. If a bag doesn’t meet the specified weight, it’s pushed aside by our product rejection system before it’s accumulated.

But We’ve Got You Covered Too

As we pointed out above, we can configure a Swifty Bagger Box Gusset system to bag a variety of products other than coffee. While our linear net weigher can be added to this system to bag whole coffee beans, it can also be set to weigh and fill your dry goods or hardware with precision. Our multi-head weighers can dispense your candy or nuts with high accuracy.

And while this coffee client chose to gather their product on a rotary table to be hand-packed into cases, we designed this system to be integrated with automated downstream packaging solutions. As a result, the client can easily remove the accumulation table and convey the sealed bags directly to an all-in-one case erecting, loading and sealing machine built by EndFlex. From there, a Z.Zag robotic palletizer can be added to move the sealed cases onto pallets, ready to be shipped to retailers and wholesalers.

Let’s Talk About Your Needs

For over 30 years we’ve partnered with companies large and small around the globe.

So, let’s talk about what you need. We can help you automate your packaging process while meeting your desired budget and production rate requirements.

Reach out today so we can get started. Or set up a visit to one of our Xperience Centers so you can see our solutions in action.