From energy powders, instant coffees, match tea powders, clean-label protein powders, electrolyte blends to smoothie kits and functional drink mixes, the beverage mix market is exploding—and the demand for scalable, hygienic, and efficient packaging automation is growing just as fast.

Whether you’re packaging into cups, stand-up pouches, jars, or form-fill-seal pillow bags, Paxiom delivers fully integrated turnkey systems——from powder fill to final pallet—designed to take your product from fill to final pallet with speed, precision, and minimal labor.

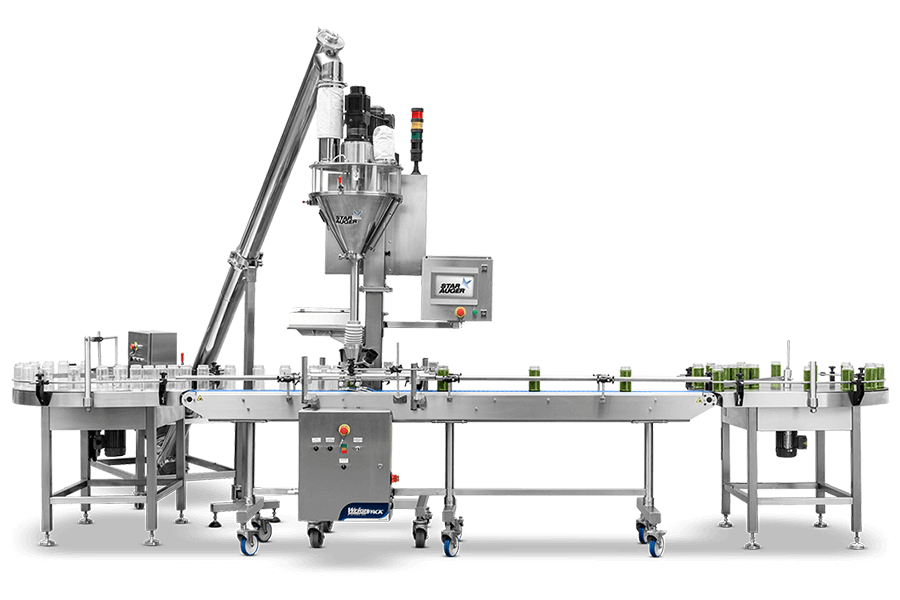

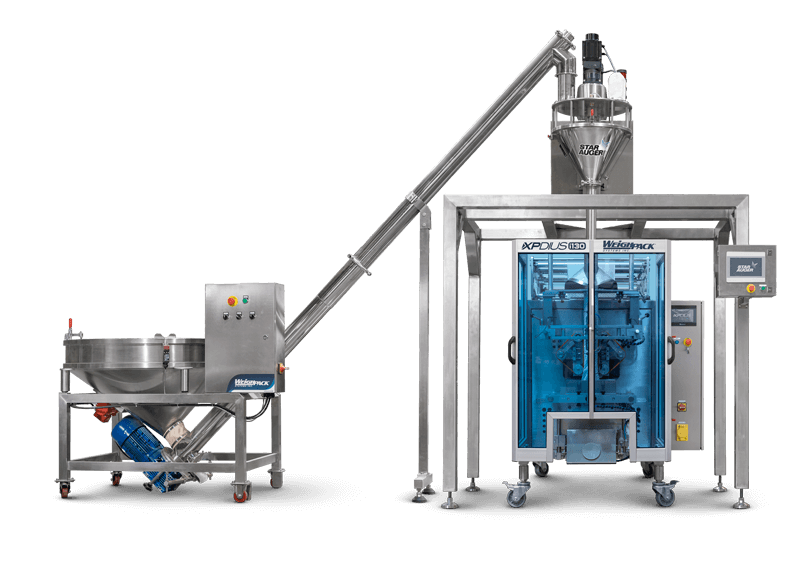

Powder Filling Made Easy: Auger Fillers + Floor-Level Screw Conveyor

At the heart of our beverage mix systems are our auger fillers, engineered specifically for accurate, clean dispensing of dry, dusty, or fine powders. And to make life easier for your operators, we offer a unique screw conveyor that gently feeds powders into the auger from a floor-level hopper. All they have to do is feed product into the hopper—no ladders, no scoops, no mess. It’s ergonomic, efficient, and ideal for production environments focused on safety and speed.

Cups: Denesting, Filling, Sealing, Check Weighing, Labeling & Beyond

For powdered drinks in cups, we offer a fully automated line:

- Cup denesters to load cups onto the conveyor

- Auger filling station for the main powder dosage

- Primolinear V-Mini for any dry granular additions like chia, oats, or sugar

- Additional Hand-fill stations for custom mix-ins (think freeze-dried fruits or superfoods)

- Integrate Cup sealing units with film or foil seal application

- Adhesive labelers to apply branding or nutritional labels to lids or sides

See it in action in our Complete Smoothie Cup Filling System video.

Pouches & Bags: SwiftyBagger Series, VerTek Series & VF 1200

Whether you’re using premade bags or forming them on-site, we’ve got flexible systems to fit your operation:

- Swifty Bagger: Opens, fills, and seals premade pouches in all formats—stand-up, gusseted, zipper, and flat-bottom. Models from entry level to high speed. Adapt to a large range of pouch sizes from small to large.

- VerTek Series: Vertically forms, fills, and seals bags from roll stock; perfect for gusseted, pillow, or quad-seal bags. Models from entry level to high performance.

- R2B: Horizontally forms, fills and seals pouches from roll stock, perfect for 3 or 4 sided seals or shaped pouches.

- VF 1200: High-speed (up to 150 bpm), supports sanitary high pressure washdown, built for heavy-duty environments with strict sanitation requirements.

All bagging options integrate with our auger fillers or dry fillers and can be customized to integrate labeling machines or printers for QR codes, batch data, or branding. Perfect for retail-ready packaging that meets compliance, traceability, and marketing needs.

Multi-Ingredient Systems: Customize Your Kit Line

For more complex beverage kits, we offer:

- Auger fill station for the base powder

- Primolinear V-Mini to dispense dry granules or inclusions

- Additional hand-fill stations for operator-added extras like flavor packs or fruits

Build full smoothie, meal-replacement, or multi-stage drink kits with ease.

Quality Control: Check weighing & Inspection

Ensure every unit meets your exacting standards with:

- Inline checkweighers to verify target weights

- Metal detectors, vision inspection, or x-ray systems to catch foreign objects or seal faults before they leave your line

Robotic Case Packing: PKR Delta & PKR Gantry

No matter the primary package, we’ve got robotic case packing options:

- PKR Delta: High-speed pick-and-place for pouches or cups

- PKR Gantry: Ideal for jars or heavier rigid containers placed into cases or trays

End-of-Line Automation: Tray Forming, Case Packing, Taping & Palletizing

Our end-of-line lineup covers it all:

- Tray formers for open-top retail display trays

- Case erectors for RSC-style boxes

- Wraparound case packers for tight, shelf-ready packaging

- EZ Tape case sealers for secure and consistent taping

- Robotic palletizers or cobots for fully automated, programmable stacking

Industry-Best Custom Conveying Solutions to Connect It All

A packaging line is only as strong as the system that connects it—and at Paxiom, we don’t just focus on filling, packaging, and palletizing. We also supply a wide range of custom sanitary conveying solutions to tie your entire beverage mix line together seamlessly.

From product loading to end-of-line palletizing, we engineer and integrate:

- Incline & exit conveyors to elevate powders or pouches with minimal footprint

- Belt conveyors for moving cups, pouches, or jars securely between stations

- Washdown conveyors built for high-hygiene zones (ideal for beverage environments)

- Transfer conveyors to maintain consistent flow between machines and eliminate manual handling

All of our conveyors are built to meet your application’s needs—whether that’s food-grade, stainless steel, easy-to-clean designs or smartly controlled conveyors with integrated sensors and reject systems.

Whether you need to move raw dry ingredients to the filler, transfer filled pouches to a labeler, or deliver sealed cases to the palletizer, our custom conveying solutions keep your production running smoothly, safely, and efficiently.

Why Paxiom Group?

We make beverage mix packaging automation simple, scalable, and seamless—all from a single solution provider:

✅Powder filling with ergonomic floor-level loading

✅ Cup, pouch, bag, or jar packaging

✅ Integrated weighing, labeling, printing, and inspection

✅ Robotic case packing, sealing, and palletizing

✅ Modular, flexible lines that grow with your production

Let’s automate your beverage mix packaging processes today! Contact us to start designing your fully automated line for boosted production efficiency, reduced product waste and increased profits: https://www.paxiom.com/paxiom-sales-inquiries/.