Introduction: Why Resilience Matters in Pharma, Nutraceutical & Medicinal Cannabis Manufacturing

In highly regulated industries like pharmaceuticals, nutraceuticals, and medicinal cannabis, manufacturing resilience is critical. Companies face strict regulatory compliance, recalls, and the need for product safety. Efficient, consistent, and flexible packaging operations reduce risks and ensure high-quality output.

Challenges in Manual Packaging

Manual packaging and hand-loading can lead to:

- Inconsistent output and errors

- Higher labor costs

- Increased risk of contamination

- Difficulty adapting to new SKUs or products

These challenges make resilient automation a necessity for modern manufacturers.

Paxiom Packaging Automation Solutions

Gummy Bottling, Capping & Labeling

Automation for nutraceuticals supports:

- Counting and weighing gummies into bottles

- Precise capping

- Accurate labeling

- Integration with vertical cartoners and case packers

Powder Bagging & Pouch Filling

Automated systems streamline the packaging of powders, ensuring:

- Accurate portioning

- Minimal contamination risk

- Rapid SKU changes with flexible modular design

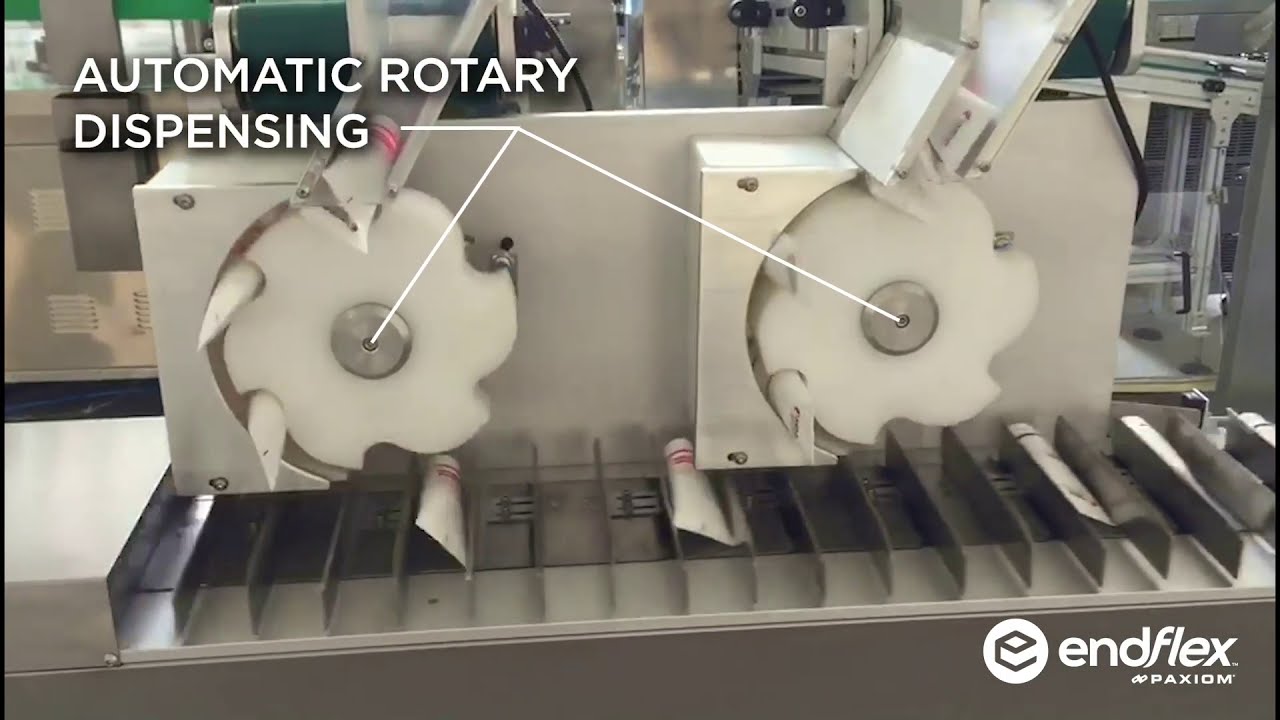

Tube Filling:

- Tube feeding and orienting for precise filling

- Automated filling and sealing of various tube types (laminate, plastic, aluminum)

Blister Pack & Medical Device Flow Wrapping

Flow wrapping solutions efficiently package:

- Medical test kits and devices

- Blister packs

- Gummy vitamins or capsules

With precise sealing and traceability for regulatory compliance.

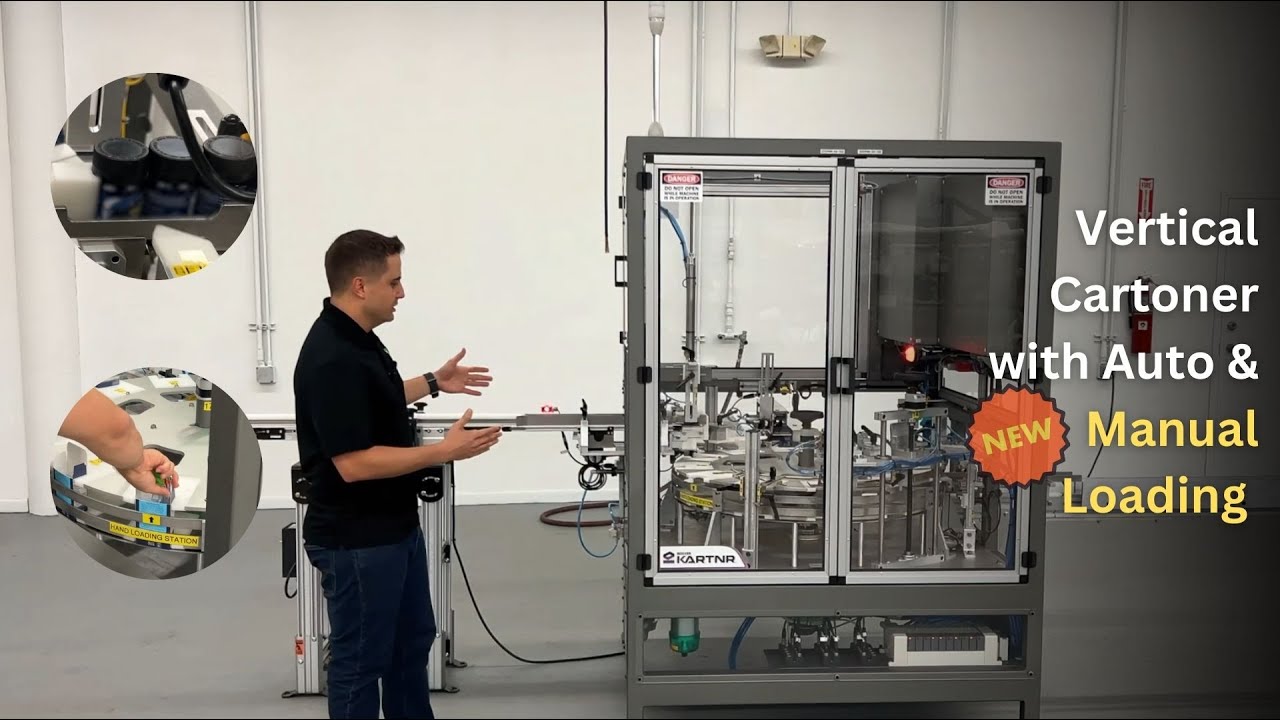

Vertical Cartoning: Kartnr-V

Compact, all-in-one vertical cartoning machines like the Kartnr-V can:

- Auto open, load, and close chipboard cartons (up to 50/min, 3000/hour)

- Handle inserts, leaflets, or top-sealed cups

- Support hand-load and auto-load simultaneously for flexible pharma/nutraceutical packaging

- Integrate robotic loading for long, narrow items or sensitive products

- Quickly change SKUs with modular setups

Regulatory Compliance

Automation ensures adherence to:

- Child-resistant packaging requirements

- Traceability standards

- Accurate labeling for pharmaceuticals, nutraceuticals, and cannabis products

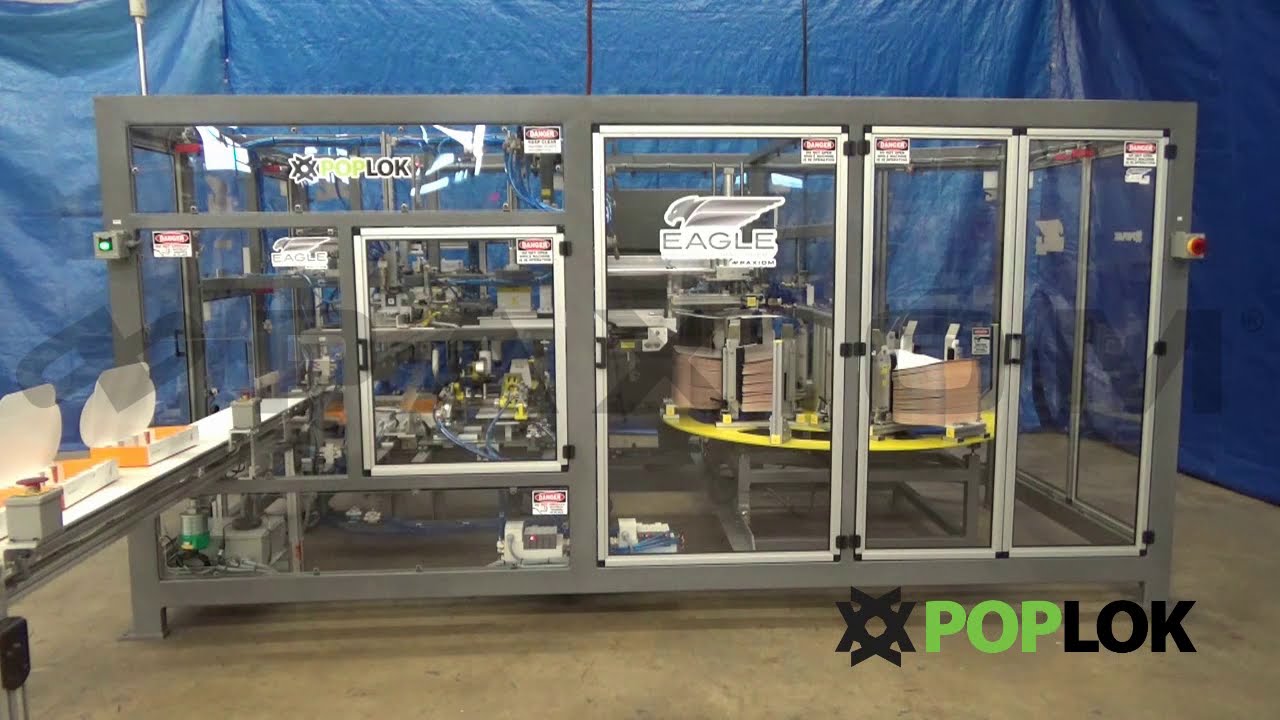

Horizontal Cartoning Automation:

- High-speed horizontal cartoning and leaflet insertion

- Integration of vision systems for quality control and inspection

Tray / Case Forming

Medical device and nutraceutical packaging lines benefit from:

- Forming carton trays with inserts

- Forming fold & tuck trays

- Forming boxes/cases with tape or glue

Wraparound Case Packing & Palletizing

- Wraparound case packing for consistent throughput

- Cobot palletizing for optimized downstream operations

Digital Tools for Validation

Leverage digital twins, vision systems, and throughput simulation to:

- Validate line performance

- Ensure consistent product handling

- Predict bottlenecks before deployment

ROI & Labor Savings

Investing in resilient automation results in:

- Reduced labor costs

- Fewer rejects and recalls

- Consistent output

- Faster SKU changeovers

Comparative Value: Pharma, Nutraceuticals & Cannabis Packaging

Packaging resilience is especially important in the medicinal cannabis space, which shares regulatory complexity with pharma and nutraceuticals. Paxiom solutions allow contract manufacturers and producers to leverage the same automation standards, speed, and compliance measures across all three sectors.

| Feature | Pharma/Nutraceuticals | Medicinal Cannabis |

| Powder Bagging | ✔️ Accurate dosing & sealing | ✔️ Hemp/cannabinoid powders |

| Gummy Bottling & Capping | ✔️ Vitamin gummies | ✔️ Cannabis edibles |

| Flow Wrapping | ✔️ Medical kits, blister packs | ✔️ Pre-rolls, edibles |

| Vertical Cartoning | ✔️ Kartnr-V, inserts, leaflets, top-sealed cups | ✔️ PET/glass jars, inserts |

| Case Packing | ✔️ Wraparound & tray forming | ✔️ Wraparound, tray & bulk packaging |

| Palletizing | ✔️ Cobot palletizing | ✔️ Cobot palletizing |

| Certification | GMP/FDA compliant | NTEP certified for preroll automation & high-precision weighing |

| Digital Tools | Digital twins, vision systems | Digital twins, vision systems |

Note: Canapa by Paxiom’s NTEP-certified weighing ensures accurate product measurement for regulated cannabis markets. Learn more about NTEP legal standards for compliance.

Case Example

A nutraceutical gummy manufacturer implemented Paxiom high speed rotary automated gummy bottling machines, achieving:

- Faster throughput with minimal human error

- Flexible handling of multiple gummy types

- Integrated tracing and compliance for regulatory reporting

Frequently Asked Questions (FAQ)

Q: What is pharma packaging automation?

A: Automation that moves, fills, and packs pharmaceutical and nutraceutical products with precision, efficiency, and compliance.

Q: How does automation support regulatory compliance?

A: Automated lines integrate traceability, child-resistant features, and precise labeling, reducing risk of recalls and ensuring FDA/GMP/NTEP compliance.

Q: How can manufacturers reduce labor costs in packaging?

A: By automating bottling, bagging, wrapping, conveying, cartoning, corrugate forming, robotic packing, sealing, labeling, and palletizing, companies reduce manual handling and errors.

Conclusion

Resilient, automated packaging operations are essential for pharma, nutraceuticals, and regulated cannabis markets. Paxiom solutions provide flexible, scalable, and compliant systems for vertical cartoning, powder filling, flow wrapping, bottle handling, labeling, case packing, and palletizing.

Contact info@paxiom.com today to request specifications, pricing, and start saving labor costs on manual packaging processes.