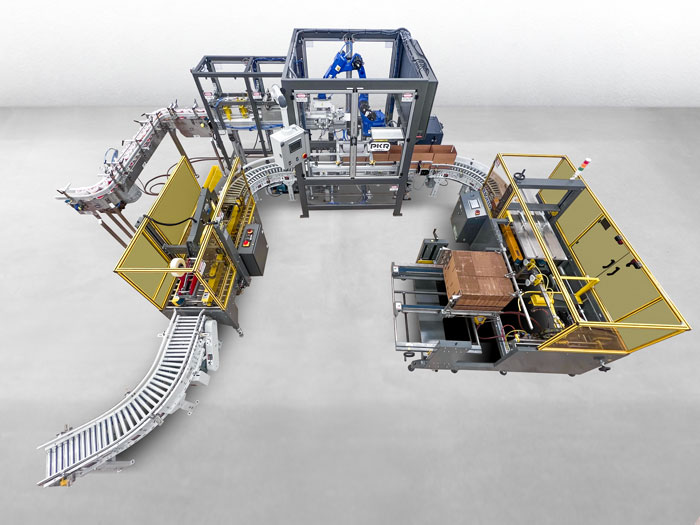

User-friendly, efficient, cost-effective case erecting and tray forming solutions are not hard to find!

We offer several machine options for these critical end of line processes tailored to meet your product specifications. So whether you are just beginning to automate your production line or looking to work these into an existing system, we can help.

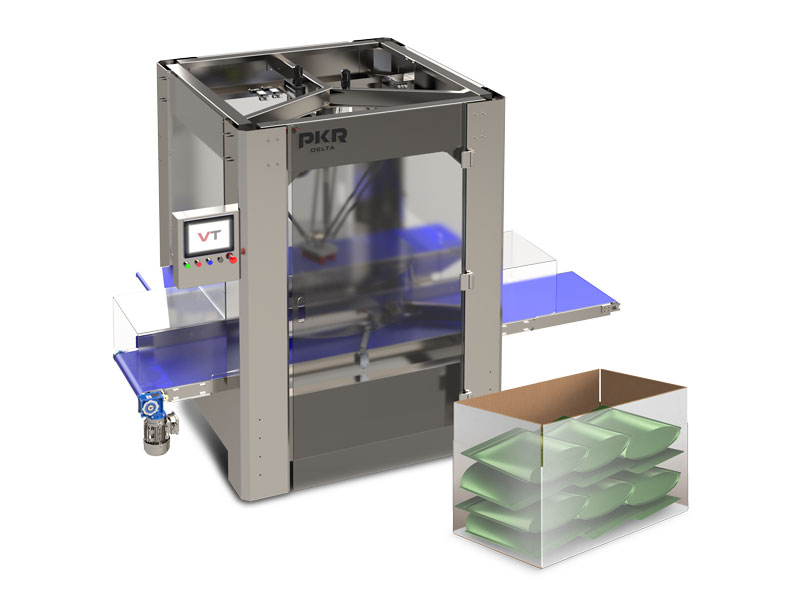

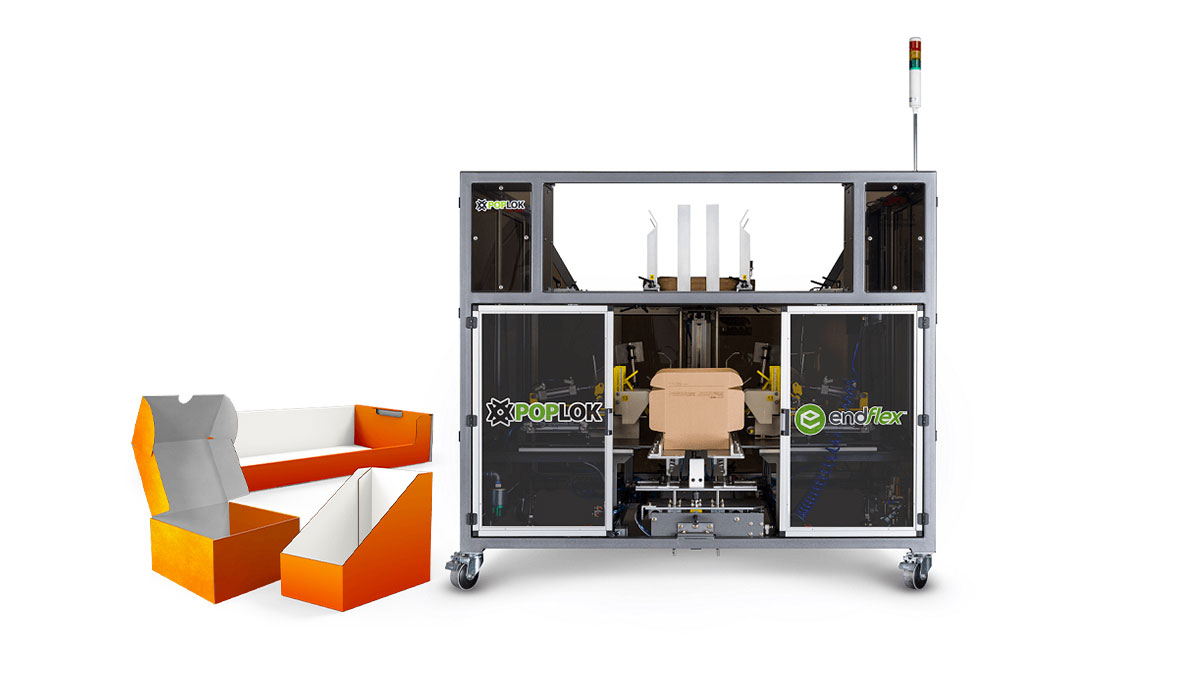

DISPLAY TRAYS & SHIPPERS

The PopLok® is the industry leader when it comes to tray forming machines for fold and tuck die-cut trays. This line of machines is engineered to the exact needs of our customers, is easy to use and does not require expensive change parts.

Ideal for packaging products such as electronics, food, consumer goods, apparel, pharmaceuticals and hardware, the PopLok is commonly used in e-commerce and home delivery when shippers and mailers are needed and is also widely used to form store displays.

From forming die-cut blanks into lidded trays or creating simple flat bottom display trays to producing sophisticated 5-tuck trays with back display walls and inserts, we have the solution you need. Stop making your corrugated trays by hand and let PopLok automatic tray former save you time and resources.

POPLOK AUTOMATIC LIDDED TRAY CLOSER

Fully automate your tray forming and packing processes with the PopLok tray closer, the ultimate solution for sealing lidded trays with unmatched precision and efficiency. The automatic incoming tray control gate ensures trays enter the system “short-side” leading, optimizing the sealing process. First, the tray dust flaps are folded 90 degrees and neatly tucked into the tray. As the tray moves to the next station, plow bars expertly guide the lid to a closed position. In the final steps, the front lip minor flaps are gracefully folded and securely tucked into front slots. The last compression station applies the perfect amount of pressure to seal the front flap with precision.

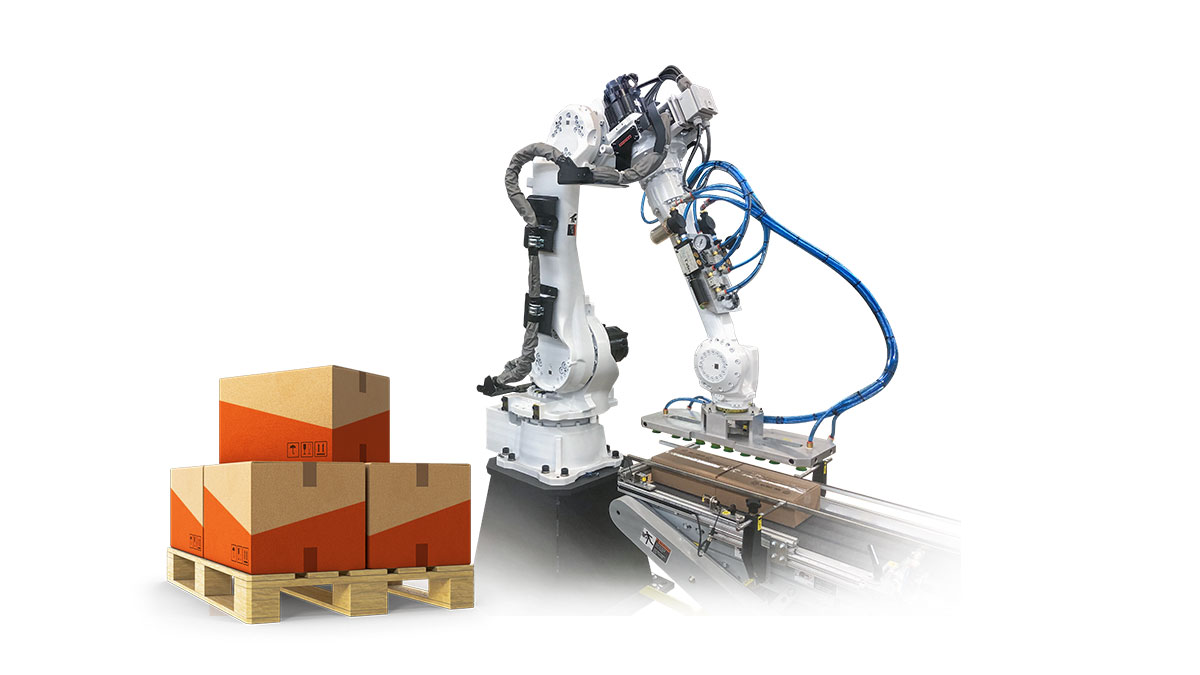

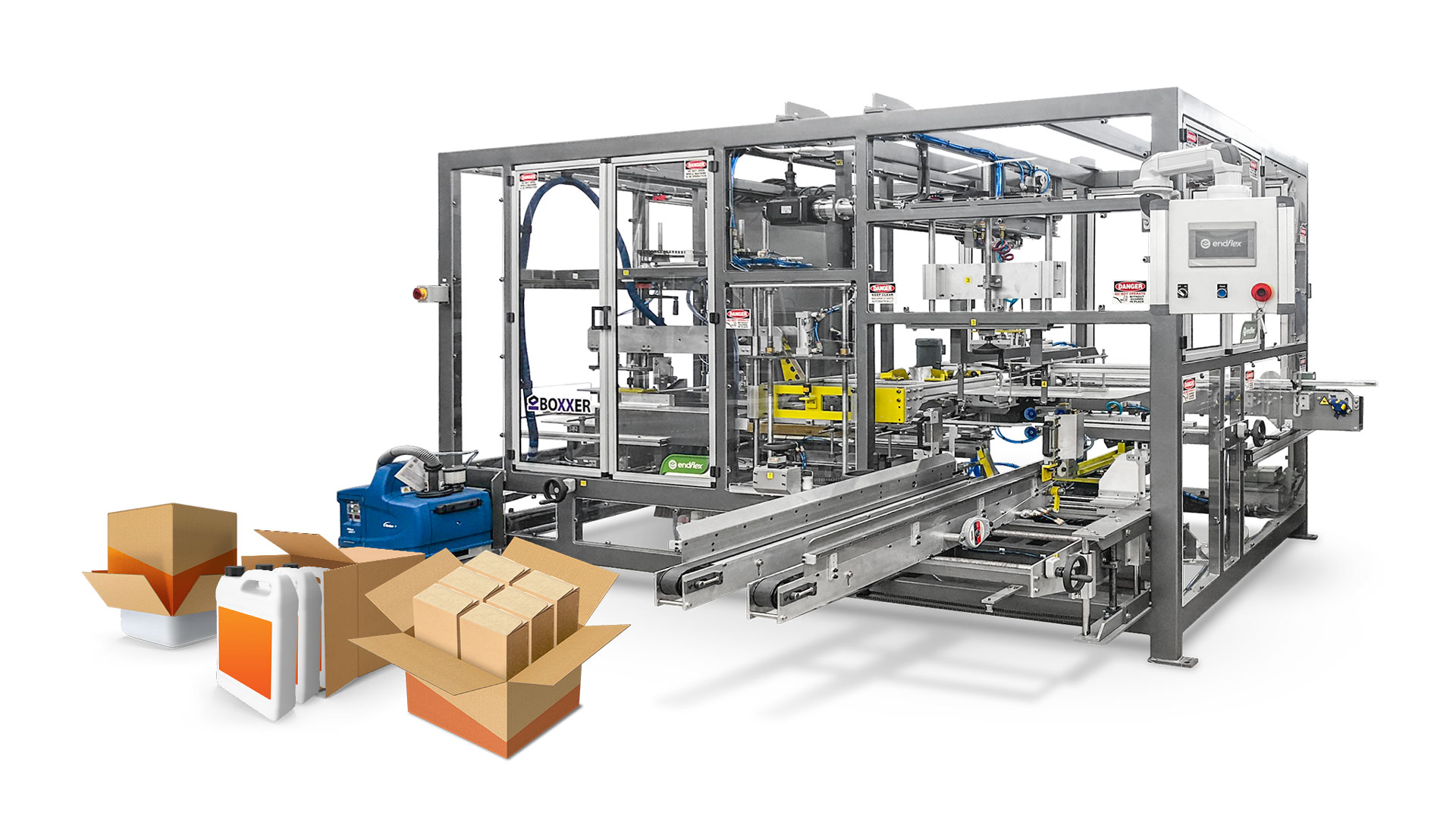

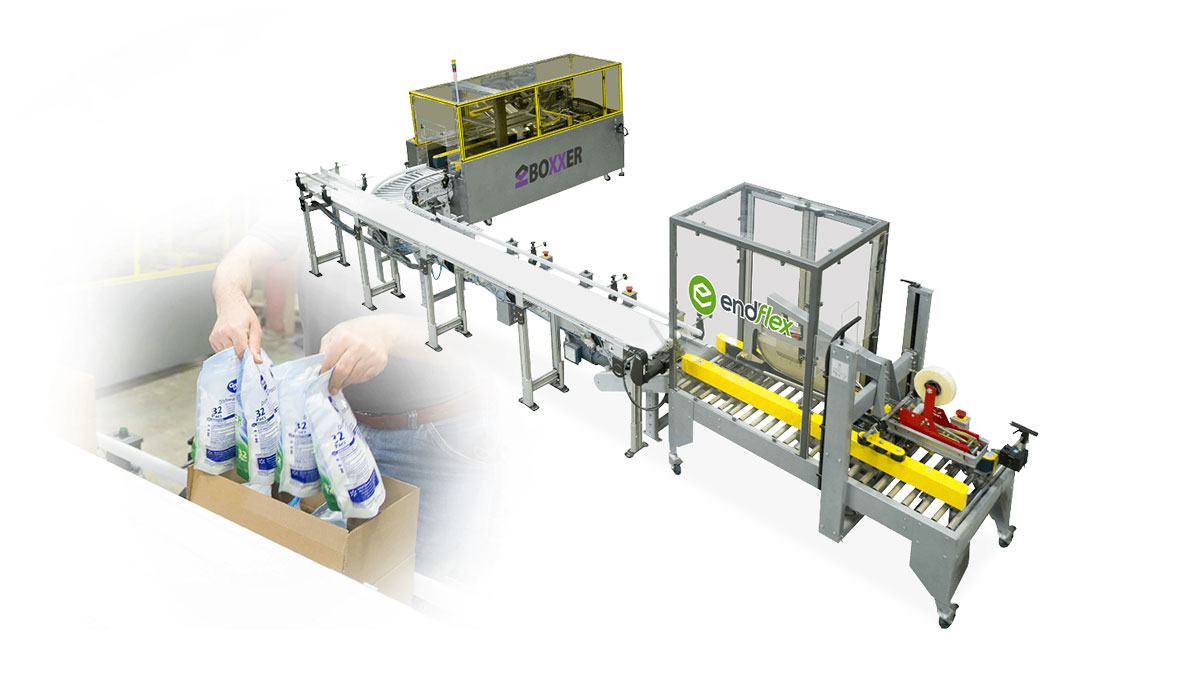

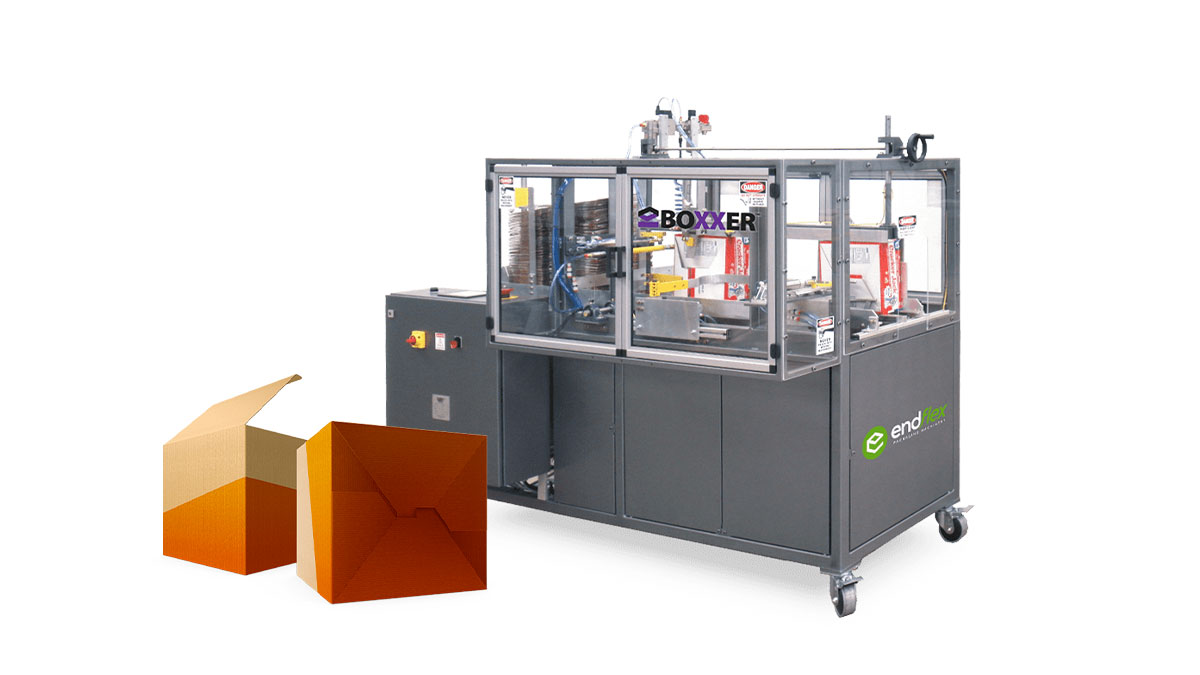

BOXXER™ CASE ERECTORS

The Boxxer case erector automatically erects corrugated RSC or HSC cases and seals them with glue or tape. Our series of case erectors include models for low, mid and high-speed production rates, offering reliable and user-friendly operation at speeds up to 35 boxes per minute. The Boxxer is inexpensive to maintain due to its mechanical drives and easy-to-access parts allow for consistent production rates from the smallest cases for coffee pods to large industrial cases for furniture.

Let us help you automate your manual corrugated box-forming processes and increase your productivity.

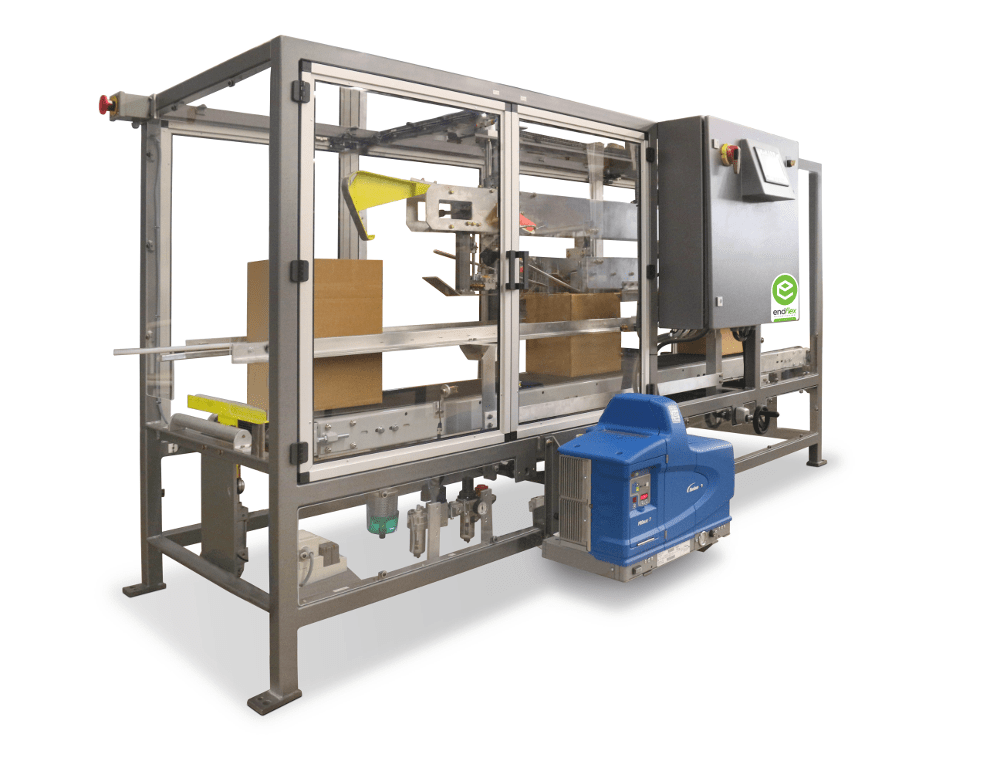

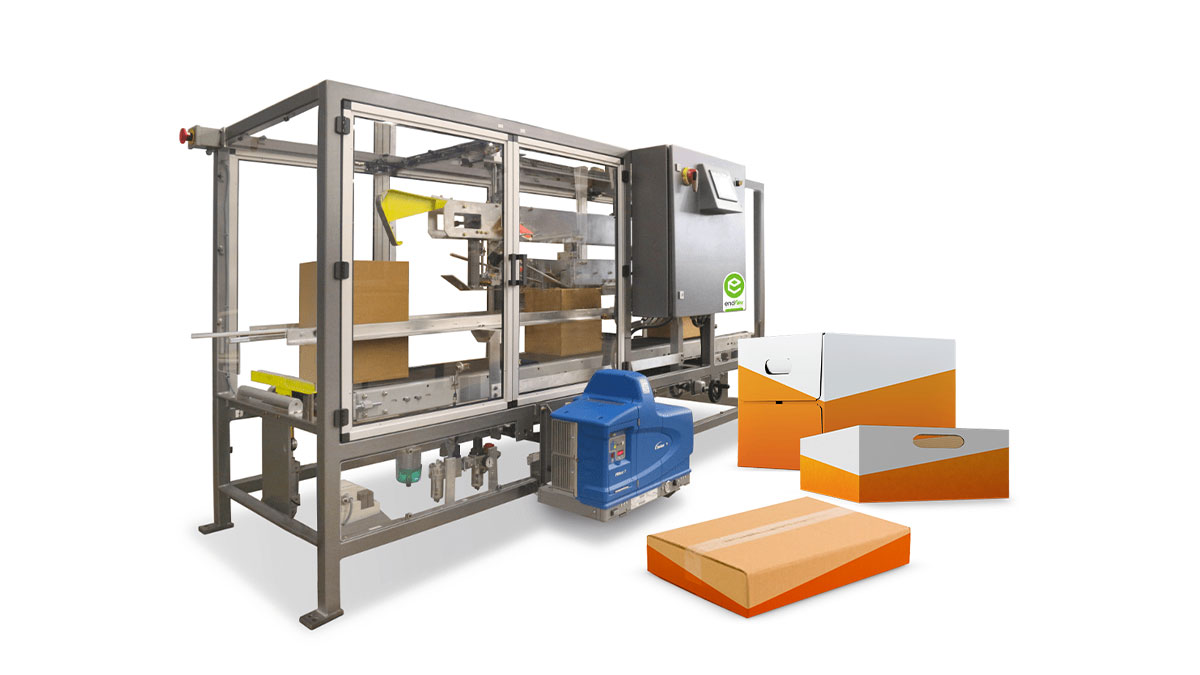

AUTOLOCK CASES

The compact Boxxer AutoLock tray and case former is designed to receive, pop open and lock corrugated cases, cartons and trays in place prior to the filling process.

Commonly used because of its tamper-evident properties and strong base for heavy products, this unit is also used in applications where a transition is needed from manual case forming to downstream automation allowing the end-user maximum production flexibility.

The AutoLock is available in painted steel or stainless steel construction.

TRAY FORMING – GLUE

The Vassoyo™ automatic tray forming machine is engineered to automatically form and glue trays for operators in virtually any industry where a tray with a lid is needed for wholesale or retail sales, including consumer goods, beverages, hardware and food to name just a few.

VASSOYO MINI DUPLEX – High Speed Glue Tray Former

The Vassoyo Mini Duplex tray former with glue comes equipped with two mandrels and two tray setups, providing versatility and flexibility in your corrugated packaging options. Its duplex design allows it to form 2 die-cut trays per cycle and its user-friendly design streamlines the transition between different tray setups, reducing downtime and increasing operational efficiency. It also offers the convenience of tool-less adjustments for the hopper and forming sections. Quick-release handles with ruler scales make fine-tuning a breeze, ensuring a seamless setup process. Utilizing a hand wheel and dial indicators, you can fine-tune the machine’s settings for optimal performance. It is not only efficient and precise but also designed with user-friendliness and operator safety in mind.

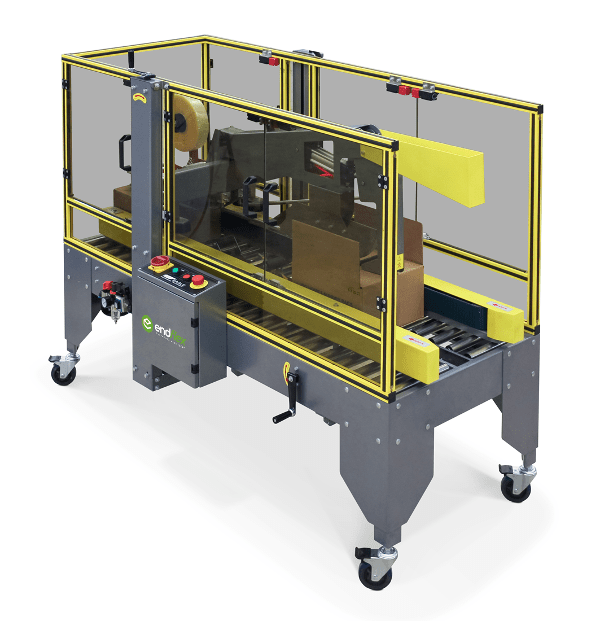

SEALING – GLUE OR TAPE

The EZ family of case sealers will take erected and filled corrugated boxes, cases and trays and tightly seal them with either hot glue or tape.

EZ-TAPE case sealers are easy to use and completely adjustable. Available in semi-automatic and automatic models, this sealer is capable of taping both the bottom and/or top of the case.

EZ-GLUE case sealers will take the erected case and seal the top of the case with hot melt glue.

Automating the case sealing process can greatly increase productivity and reduce manual repetitive labor.

Ready to Supercharge Your Production? Contact us for pricing & ROI today.